MW61 series oval electromagnetic chuck

Electromagnetic chuck description

- Product name: MW61 series oval electromagnetic chuck

- Alias: electromagnet lifting suction cup lifting magnet

- Model specifications: MW61

- Category: Electromagnetic spreader

- Product Origin: Xinxiang, Henan

- Non-standard customization: Undertake non-standard customization

- In stock or not: customized production

- Production cycle: 7~ 10 days

- Scope of supply: Nationwide

- Delivery method: self-pickup or consignment

- Whether to install: Installation is extra

- After-sales service: one year warranty

- Shipping area: Changyuan, Xinxiang, Henan

Electromagnetic chuck parameters

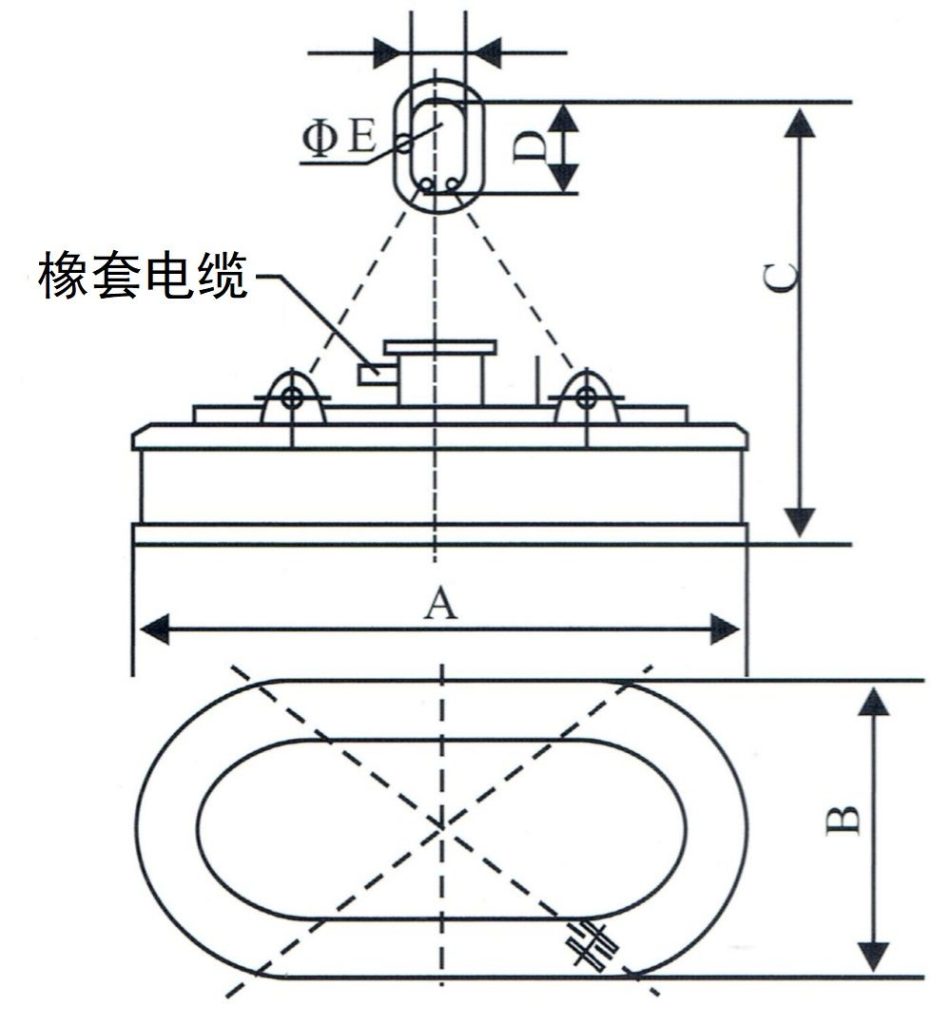

Dimensional drawing of MW61 series oval electromagnetic chuck

MW61 series (normal temperature type) oval electromagnetic chuck technical specifications parameter table

| Main technical parameters of normal temperature oval (voltage: DC=220V, power duration TD=75%) | ||||||||||

| model | MW61-200150L/1-75 | MW61-250150L/1-75 | MW61-250200L/1-75 | MW61-300150L/1-75 | MW61-300200L/1-75 | MW61-400150L/1-75 | MW61-400200L/1-75 | MW61-400250L/1-75 | ||

| Overall dimensions (mm) | A | 2000 | 1500 | 2500 | 3000 | 3000 | 4000 | 4000 | 4000 | |

| B | 1500 | 1500 | 2000 | 1500 | 2000 | 1500 | 2000 | 2500 | ||

| C | 1300 | 1300 | 1300 | 1700 | 1700 | 1900 | 1900 | 1900 | ||

| D | 250 | 250 | 250 | 280 | 280 | 280 | 280 | 300 | ||

| E | 180 | 180 | 180 | 210 | 210 | 210 | 210 | 210 | ||

| F | 60 | 60 | 60 | 70 | 70 | 80 | 80 | 80 | ||

| self weight (kg) | 6200 | 7000 | 7800 | 8500 | 9000 | 12000 | 14500 | 17000 | ||

| Power(kw) | 18.3 | 20.9 | 22.5 | 23.7 | 28.3 | 29.17 | 33.8 | 36.3 | ||

| Current(A) | 83.3 | 95 | 102 | 108 | 129 | 132 | 154 | 165 | ||

| Suction and lifting capacity (kg) | Large steel ingot | 1400/800 | 1800/900 | 2000/1200 | 2200/1300 | 2800/1600 | 3500/2000 | 4000/2400 | 6500/3100 | |

| cast iron ingot | 2200/1400 | 2800/1500 | 3200/1900 | 3500/2000 | 4000/2500 | 4600/3000 | 6000/3500 | 8500/5000 | ||

| Chips | 1000/600 | 1300/800 | 1500/1000 | 1800/1100 | 2200/1300 | 2600/1600 | 3000/1800 | 5000/2300 | ||

| Grouped equipment | Rectifier control equipment | STQL-25E | STQL-32E | STQL-38E | STQL-45E | |||||

| cable reel | JTA125-15-2 | JTA175-15-2 | JTA200-15-2 | |||||||

| cable connector | DL-202 | |||||||||

| Note: According to the different needs of users and the actual conditions of the work site, suction cups with specifications other than these technical parameters can be designed and manufactured. | ||||||||||

MW61 series (high temperature resistant type) oval electromagnetic chuck technical specifications parameter table

| High temperature resistant oval (voltage: DC=220V, power continuity rate TD=75%, the temperature of the material to be sucked is 100~700℃) main technical parameters | ||||||||||

| model | MW61-200150L/2-75 | MW61-250150L/2-75 | MW61-250200L/2-75 | MW61-300150L/2-75 | MW61-300200L/2-75 | MW61-400150L/2-75 | MW61-400200L/2-75 | MW61-400250L/2-75 | ||

| Overall dimensions (mm) | A | 2000 | 1500 | 2500 | 3000 | 3000 | 4000 | 4000 | 4000 | |

| B | 1500 | 1500 | 2000 | 1500 | 2000 | 1500 | 2000 | 2500 | ||

| C | 1300 | 1300 | 1300 | 1700 | 1700 | 1900 | 1900 | 1900 | ||

| D | 250 | 250 | 250 | 280 | 280 | 280 | 280 | 300 | ||

| E | 180 | 180 | 180 | 210 | 210 | 210 | 210 | 210 | ||

| F | 60 | 60 | 60 | 70 | 70 | 80 | 80 | 80 | ||

| self weight (kg) | 6600 | 7400 | 8300 | 9000 | 9500 | 13000 | 1600 | 19000 | ||

| Power(kw) | 16.5 | 18.9 | 20.9 | 21.6 | 22.9 | 25.9 | 28.3 | 33.8 | ||

| Current(A) | 75 | 86 | 95 | 98 | 104 | 118 | 129 | 154 | ||

| Suction and lifting capacity (kg) | Large steel ingot | 1400/800 | 1800/900 | 2000/1200 | 2200/1300 | 2800/1600 | 3500/2000 | 4000/2400 | 6500/3100 | |

| cast iron ingot | 2200/1400 | 2800/1500 | 3200/1900 | 3500/2000 | 4000/2500 | 4600/3000 | 6000/3500 | 8500/5000 | ||

| Chips | 1000/600 | 1300/800 | 1500/1000 | 1800/1100 | 2200/1300 | 2600/1600 | 3000/1800 | 5000/2300 | ||

| Grouped equipment | Rectifier control equipment | STQL-25E | STQL-32E | STQL-38E | STQL-45E | |||||

| cable reel | JTA125-15-2 | JTA175-15-2 | JTA200-15-2 | |||||||

| cable connector | DL-202 | |||||||||

| Note: According to the different needs of users and the actual conditions of the work site, suction cups with specifications other than these technical parameters can be designed and manufactured. | ||||||||||