Four rope grab

Four rope grab instructions

- Product name: Four rope grab

- Product Origin: Xinxiang, Henan

- Non-standard customization: Non-standard customization is available

- Whether in stock: Partially in stock

- Production cycle: 15~30 days

- Scope of supply: Nationwide

- Delivery method: self-pickup/consignment

- Whether to install: Installation is extra

- After-sales service: one year warranty

The working principle of the four-rope grab:

On the bridge crane, there are two sets of double-row rope drums. Each set of drums leads to two sets of steel wire ropes. One set of two steel wire ropes are tied to the inclined shells or (sling rope rings and bundles) at both ends of the grab balance frame. Rope bolt), used to support the wire rope. The other group of two is used for opening and closing wire ropes. They pass through the sheave pulley, the head pulley, and the lower beam pulley to form a pulley group, which plays the role of opening and closing the grab. When the work starts, support the wire rope to lift the grab bucket in the appropriate position, and then lower the opening and closing wire rope. At this time, the dead weight of the lower beam forces the bucket part to open centered on the major axis of the lower beam. When the head opens to the two ear plates, When the collision blocks collide, the bucket is opened to the maximum limit. When the grab is opened, the center distance between the upper beam pulley and the lower beam pulley is increased, and then the steel wire rope is supported to fall, and the opened grab bucket is dropped on the loose accumulation to be grabbed, and then the opening and closing wire rope is gathered, and the upper beam pulley and the lower beam pulley are connected. The center distance of the lower beam pulley returns to its original position, thus completing the process of grabbing materials. The closed bucket is filled with materials. Finally, the supporting wire rope and the opening and closing wire rope are lifted simultaneously. The entire grab is also lifted and moved to the required unloading ground by driving. The bucket is opened to unload the grabbed materials.

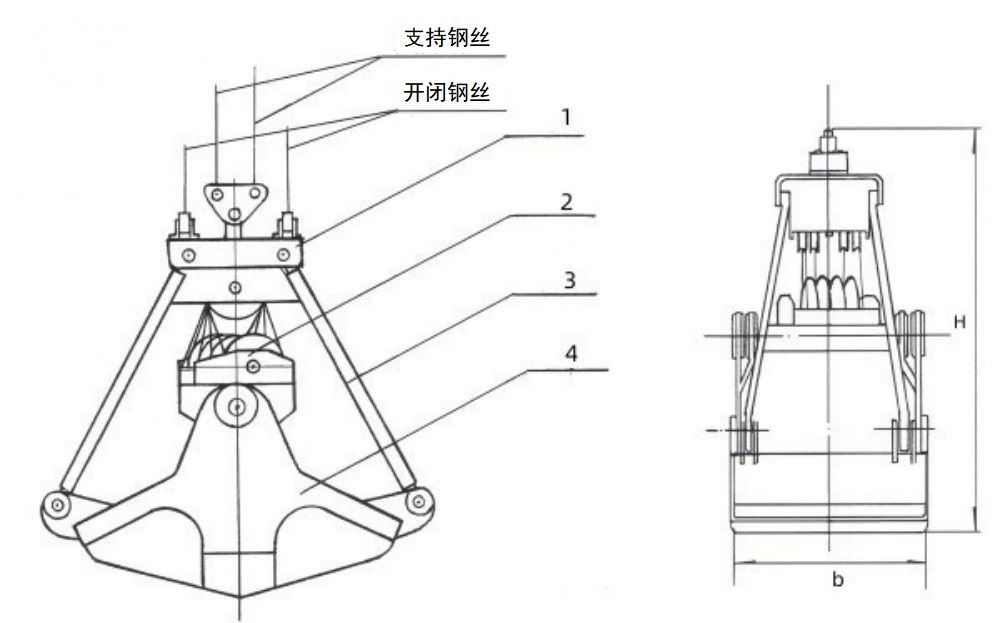

Schematic diagram of the appearance and structure of a four-rope grab bucket

Four-rope grab technical parameters and overall dimensions (Table 1)

| Model | Grab bucket volume m³ | Grab type | Material specific gravity (t/m³) | Grab material weight t | Pulley magnification | Steel rope diameter mm | Opening and closing time seconds | Equipped with traveling tonnage | Pulley diameter mm | Grab bucket self weightt | Grab bucket total height H(mm) | Maximum opening size D(mm) | Bucket size axbxh | Remark |

| U1 | 1 | Heavy | >1.8-1.9 | 1.8-1.9 | 5 | F14 | 14 | 5 | Φ350 | 2.065 | 2635 | 2544 | 1850x1150x673 | |

| U2 | 1.5 | middle | >1-1.8 | 1.5-2.1 | 5 | F14 | 12.5 | 5 | Φ350 | 2.235 | 2765 | 2700 | 2150x1250x745 | |

| U3 | 2.5 | light | >0.5-1 | 1.25-2.5 | 3 | F14 | 8 | 5 | f350 | 2.285 | 2985 | 3200 | 2350x1500x927 | |

| U4 | 2 | Heavy | >1.8-2.9 | >3.6-5.8 | 5 | F18 | 15 | 10 | Φ500 | 3.898 | 3184 | 3070 | 2410x1320x826 | |

| U5 | 3 | middle | >1.0-1.8 | 3-5.4 | 5 | F18 | 15 | 10 | Φ500 | 4.4 | 3301 | 3200 | 2650x1550x900 | |

| U6 | 5 | light | >0.5-1 | 3 | F18 | 10 | 10 | Φ500 | 4.616 | 3549 | 3790 | 2950x1900x1090 | ||

| U7 | 3 | Heavy | >1.8-2.9 | 5 | Φ21.5 | 15.3 | 15 | Φ610 | 6.284 | 3726 | 3326 | 2616x1700x886 | ||

| U8 | 4.5 | middle | >1-1.8 | >4.5-8.1 | 5 | Φ21.5 | 15.3 | 15 | Φ610 | 6.988 | 3946 | 3756 | 2956x1800x1041 | |

| U9 | 3 | middle | 1-2 | 3-6 | 5 | F18 | 16.2 | 10 | Φ500 | 4.431 | 3315 | 3200 | 2500x1722x630 | |

| U21 | 2.5 | light | 0.86 | 2.15 | 4 | F16 | 10.3 | 5 | Φ400 | 2.83 | 3350 | 3150 | 2150x1500x920 | |

| U25 | 3 | middle | >1-1.7 | 3-5.4 | 5 | Φ19.5 | 11 | 10 | Φ500 | 4.868 | 3172 | 3400 | 2400x1748x780 | |

| U26 | 3 | middle | 1.7 | 5.13 | 5 | Φ19.5 | 11 | 10 | Φ500 | 5.03 | 3172 | 3400 | 2400x1748x780 | toothed |

| U27 | 2 | middle | >1-1.2 | 2-2.4 | 5 | F16 | 12 | 5 | Φ400 | 2.5 | 2860 | 3000 | 2150x1500x820 | |

| U41 | 4 | Heavy | >2.5 | 10 | 5 | F27 | 14 | 20 | Φ700 | 8.045 | 4215 | 4200 | 2800x1800x930 | |

| U43 | 1 | Heavy | >2-3 | 2-3 | 5 | F16 | 11.6 | 5 | Φ400 | 2.318 | 2662 | 2600 | 2100x1092x577 | |

| U44 | 1 | Heavy | >2-3 | 2-3 | 5 | F16 | 11.6 | 5 | Φ400 | 2.370 | 2662 | 2600 | 2100x1092x577 | toothed |

| U45 | 1.5 | middle | >1-1.9 | 1.5-2.85 | 5 | F16 | 11.6 | 5 | Φ400 | 2.515 | 2667 | 2600 | 2100x1392x577 | |

| U46 | 1.5 | middle | >1-1.9 | 1.5-2.85 | 5 | F16 | 11.6 | 5 | Φ400 | 2.448 | 2667 | 2600 | 2100x1392x577 | The balance beam opens |

| U47 | 3 | light | 0.92 | 2.75 | 3 | F16 | 7.4 | 5 | Φ400 | 2.414 | 2926 | 3000 | 2200x1796x841 | |

| U47A | 2.5 | light | 0.92 | 2.3 | 3 | F16 | 7.4 | 5 | Φ400 | 2.167 | 2926 | 2200x1600x841 | ||

| U48 | 2 | Heavy | >2-3 | 4-6 | 5 | Φ19.5 | 16.2 | 10 | Φ500 | 3.927 | 3315 | 3200 | 2500x1396x680 | |

| U48A | 2 | Heavy | >2.1-2.6 | 4.2-5.2 | 6 | Φ19.5 | 15.2 | 10 | Φ350 | 4.020 | 3160 | 3000 | 2260x1300x875 | |

| U49 | 2 | Heavy | >2.7 | 5.385 | 5 | Φ19.5 | 15.6 | 10 | Φ500 | 4.663 | 3530 | 3300 | 2500x1398x680 | |

| U50 | 3 | middle | >1-2 | 3-6 | 5 | Φ19.5 | 16.2 | 10 | Φ500 | 4.273 | 3315 | 3200 | 2500x1896x680 | |

| U51 | 3 | middle | 1-2 | 3-6 | 5 | Φ19.5 | 16.2 | 10 | Φ500 | 4.394 | 3315 | 3200 | 2500x1896x680 | toothed |

| U52 | 6 | light | 1 | 6.04 | 3 | Φ19.5 | 9.5 | 10 | Φ500 | 3.960 | 3615 | 3700 | 2800x2196x1050 | |

| U53 | 3 | Heavy | 2.5 | 7 | 5 | Φ23.5 | 14 | 15 | φ600 | 6.860 | 3850 | 3400 | 2720x1600x850 | |

| U54 | 3 | Heavy | 2.5 | 7 | 5 | Φ23.5 | 14 | 15 | Φ600 | 7.229 | 3850 | 3400 | 2700x1600x850 | toothed |

| U55 | 4.5 | middle | 1.7 | 7.65 | 5 | Φ23.5 | 16.3 | 15 | Φ600 | 7.405 | 4130 | 4050 | 3000x1992x850 | toothed |

| U63 | 3 | middle | 1-2 | 3-6 | 5 | Φ19.5 | 14.2 | 10 | Φ500 | 4.306 | 3315 | 3200 | 2500x1396x680 | Parallel girders open |

| U67 | 1.5 | middle | 1-1.9 | 1.5-2.85 | 5 | F16 | 9 | 5 | Φ400 | 2.468 | 2968 | 2800 | 2120x1300x698 | |

| U69 | 1.5 | middle | 1-1.9 | 1.5-2.85 | 5 | F16 | 11.6 | 5 | Φ400 | 2.544 | 2867 | 2600 | 2100x1392x577 | toothed |

| U101 | 0.75 | overweight | >2.5-3.3 | 1.8-2.4 | 6 | F16 | 11.9 | 5 | Φ400 | 2.479 | 2735 | 2340 | 1650x1054x540 | |

| U102 | 0.75 | overweight | >2.5-3.3 | 1.8-2.4 | 6 | F16 | 11.9 | 5 | Φ400 | 2.546 | 2735 | 2340 | 1650x1054x620 | toothed |

| U103 | 3 | middle | 1-1.9 | 5.2 | 6 | Φ19.5 | 11.9 | 10 | Φ500 | 5.586 | 3443 | 3400 | 2400x1640x850 | toothed |

| U105 | 1 | Heavy | 1.7-2.5 | 1.7-2.5 | 6 | F16 | 11.8 | 5 | Φ400 | 2.506 | 2835 | 2530 | 1800x1238x600 1800x1238x600 | |

| U106 | 1 | Heavy | 1.7-2.5 | 1.7-2.5 | 6 | F16 | 11.8 | 5 | Φ400 | 2.568 | 2835 | 2530 | 1800x1238x600 | toothed |

| U160 | 1 | Heavy | 1.7-2.5 | 1.7-2.5 | 6 | F16 | 11.8 | 5 | Φ400 | 2.506 | 2835 | 2530 | 1800x1238x600 | |

| U109 | 1.5 | middle | 1.0-1.7 | 1.5-2.55 | 5 | F16 | 11.6 | 5 | Φ400 | 2.549 | 2935 | 2740 | 1950x1444x655 | |

| U110 | 1.5 | middle | 1.0-1.7 | 1.5-2.55 | 5 | F16 | 11.6 | 5 | Φ400 | 2.615 | 2935 | 2740 | 1950x1444x655 | toothed |

Four-rope grab technical parameters and overall dimensions (Table 2)

| model | Grab bucket volume m³ | Grab type | Material specific gravity (t/m³) | Grab material weight t | Pulley magnification | Steel rope diameter mm | Opening and closing time seconds | Equipped with traveling tonnage | Pulley diameter mm | Grab bucket self weightt | Grab bucket total height H(mm) | Maximum opening size D(mm) | Bucket size axbxh | Remark |

| U111 | 1.5 | middle | 1-1.7 | 1.5-2.85 | 5 | F16 | 11.6 | 5 | Φ400 | 2.546 | 2935 | 2740 | 1950x1444x655 | Parallel girders open |

| U113 | 2.5 | light | >1 | 2.5 | 4 | F16 | 9 | 5 | Φ400 | 2.633 | 3135 | 3120 | 2200x1634x800 | |

| U115 | 1.5 | overweight | 2.5-3.3 | 3.75-4.95 | 6 | Φ19.5 | 18 | 10 | Φ500 | 4.730 | 3490 | 2920 | 1960x1416x650 | |

| U116 | 1.5 | overweight | 2.5-3.3 | 3.75-4.95 | 6 | Φ19.5 | 18 | 10 | Φ500 | 4.793 | 3570 | 3080 | 1960x1416x730 | toothed |

| U119 | 2 | Heavy | 1.8-2.5 | 3.6-5 | 6 | Φ19.5 | 17.9 | 10 | f 500 | 4.850 | 3640 | 3220 | 2200x1528x730 | |

| U120 | 2 | Heavy | 1.8-2.5 | 3.6-5 | 6 | Φ19.5 | 17.9 | 10 | Φ500 | 4.913 | 3720 | 3380 | 2200x1528x810 | toothed |

| U123 | 3 | middle | >1-1.7 | 3-5.1 | 5 | Φ19.5 | 16.5 | 10 | Φ500 | 4.803 | 3747 | 3430 | 2400x1764x782 | |

| U124 | 3 | middle | 1-1.7 | 3-5.1 | 5 | Φ19.5 | 16.5 | 10 | Φ500 | 4.866 | 3747 | 3430 | 2400x1764x782 | toothed |

| U126 | 3 | middle | 1-1.7 | 5 | 5 | Φ19.5 | 10 | 10 | Φ500 | 4.966 | 3827 | 3430 | 2400x1700x782 | |

| U126A | 3 | middle | 1-1.7 | 5 | 5 | Φ19.5 | 10 | 10 | Φ500 | 4.997 | 3827 | 3430 | 2400x1700x782 | Parallel girders open |

| U127 | 5 | light | ≤1 | 5 | 3 | Φ19.5 | 11 | 10 | Φ500 | 4.80 | 3990 | 3800 | 2700x2060x1000 | |

| U129 | 2.5 | overweight | >2.5-3.3 | 6.25-8.25 | 6 | Φ23.5 | 16 | 15 | Φ600 | 8.155 | 4285 | 3430 | 2350x1628x780 | |

| U130 | 2.5 | overweight | >2.5-3.3 | 6.25-8.25 | 6 | Φ23.5 | 16 | 15 | Φ600 | 8.305 | 4285 | 3750 | 2350x1628x880 | toothed |

| U133 | 3.2 | Heavy | >1.7-2.5 | 5.44-8 | 6 | Φ23.5 | 16.2 | 15 | Φ600 | 8.008 | 4455 | 3750 | 2600x1792x880 | |

| U134 | 3.2 | Heavy | >1.7-2.5 | 5.44-8 | 6 | Φ23.5 | 16.2 | 15 | Φ600 | 8.159 | 4555 | 3950 | 2600x1792x980 | |

| U137 | 4.8 | middle | >1-1.7 | 4.8-8.16 | 5 | Φ23.5 | 14 | 15 | Φ600 | 7.993 | 4605 | 4050 | 2820x2078x960 | |

| U138 | 4.8 | middle | >1-1.7 | 4-6.4 | 5 | F24 | 14 | 15 | Φ600 | 8.143 | 4605 | 4380 | 2820x2078x960 | toothed |

| U141 | 8 | light | ≤1 | 8 | 3 | Φ23.5 | 12 | 15 | Φ600 | 7.84 | 4775 | 4380 | 3200x2350x1150 | |

| U143 | 3 | overweight | >2.5-3.3 | 7.5-9.5 | 6 | F28 | 18 | 20 | Φ700 | 9.78 | 4695 | 3800 | 2400x1892x830 | |

| U144 | 3 | overweight | >2.5-3.3 | 7.5-9.5 | 6 | F28 | 18 | 20 | Φ700 | 9.927 | 4795 | 4000 | 2400x1892x830 | toothed |

| U147 | 4 | Heavy | >1.7-2.6 | 5-10 | 6 | F28 | 18.2 | 20 | Φ700 | 9.976 | 4795 | 4000 | 2900x1892x1070 | |

| U148 | 4 | Heavy | >1.7-2.6 | 5-10 | 6 | F28 | 18.2 | 20 | Φ700 | 10.123 | 4895 | 4000 | 2900x1892x1170 | toothed |

| U149 | 4 | Heavy | >1.7-2.6 | 5-10 | 6 | F28 | 18.2 | 20 | Φ700 | 9.986 | 4795 | 4000 | 2900x1892x1170 | Parallel girders open |

| U151 | 6 | middle | >1-1.7 | 5-9.3 | 5 | F28 | 19 | 20 | Φ700 | 10.098 | 4955 | 4500 | 3200x2288x1060 | |

| U152 | 6 | middle | >1-1.7 | 5-9.3 | 5 | F28 | 19 | 20 | Φ700 | 10.287 | 5055 | 4720 | 3200x2288x1160 | toothed |

| U155 | 10 | light | ≤1 | 5-9 | 3 | F28 | 13 | 20 | Φ700 | 9.812 | 5215 | 5000 | 3500x2478x1310 | |

| U162 | 2.5 | light | 1 | 2.8 | 4 | F16 | 9 | 5 | Φ400 | 2.633 | 3135 | 3120 | 2200x1544x800 | |

| U163 | 4 | Heavy | 1.7-2.6 | 5-10 | 6 | F32 | 18.2 | 20 | Φ700 | 9.966 | 4795 | 4000 | ||

| Z5 | 1 | Heavy | 2.1-3 | 1.5-2.63 | 6 | Φ13.5 | 12.2 | 5 | Φ300 | 2.524 | 2708 | 2710 | 1930x1050x798 | |

| Z15 | 1.5 | middle | >1.1-2 | 1.5-1.8 | 5 | F16 | 13 | 5 | Φ300 | 2.35 | 2710 | 2770 | 2130x1250x830 | |

| Z25 | 2.5 | light | 0.6-1 | 1.5-2.5 | 4 | F16 | 10.03 | 5 | Φ350 | 2.493 | 2890 | 3150 | 2330x1500x920 | |

| K6 | 2.56 | Heavy | 3 | 7.5 | 6 | F22 | 15 | Φ500 | 7.596 | 3752 | 3150 | 2638x1672x962 | ||

| SZ1-0 | 4 | Heavy | 2.1-2.5 | 1-10 | 6 | F32 | 19.3 | 20 | Φ520 | 7.954 | 3730 | 3600 | 2880x1796x990 | |

| SZ1-1 | 4 | Heavy | 2.1-2.5 | 1-10 | 6 | F32 | 19.3 | 20 | Φ520 | 8.247 | 3730 | 3600 | 2880x1796x990 | toothed |

| S | 1 | middle | 0.8-1.2 | 0.8-1.2 | 3 | F13 | 3 | Φ300 | 1.460 | 2224 | 2210 | 1620x900x670 | ||

| U1GT | 1 | Heavy | 1.8-2.7 | ≤2.3 | 5 | F16 | 11 | 5 | Φ400 | 2.290 | 2798 | 2500 | 1980x1130x520 | |

| U2GT | 1 | Heavy | 1.8-2.7 | ≤2.3 | 5 | F16 | 11 | 5 | Φ400 | 2.386 | 2798 | 2500 | 1980x1130x520 | toothed |

| U3GT | 1.5 | middle | >1-1.8 | 2.7 | 5 | F16 | 13 | 5 | φ400 | 2.307 | 2931 | 2800 | 2360x1250x690 | |

| U4GT | 1.5 | middle | >1-1.8 | 1.5-2.85 | 5 | F16 | 13 | 5 | Φ400 | 2.403 | 2931 | 2800 | 2360x1250x690 | toothed |

| U5GT | 2.5 | middle | ≤1 | 2.5 | 4 | F16 | 10.3 | 5 | Φ400 | 2.570 | 3148 | 3166 | 2150x1496x580 |

Four-rope grab manufacturers provide users with ordinary four-rope grabs, four-rope penal grabs and double-rope grabs, single-rope suspension grabs, electro-hydraulic double-flap/multi-flap grabs (mechanical multi-flap grabs) , electric motor grab, electric stainless steel grab (brewing grab, distiller’s grain grab), scissor grab, wood grab and rope-type rectangular grab for cleaning, dredging grab, four-rope leak-proof double-flap grab, Design and manufacturing (customization) of complete sets of grab products such as wireless remote control double-flap grabs, semi-scissor grab buckets, and excavator-specific grab buckets, as well as accessories wholesale and retail, installation, repair and maintenance services, and more national standard/non-standard/special purpose Please consult customer service for grab manufacturer brand, technical parameters, installation size drawings, and price.