Operating procedures for electric hoists of bridge cranes (single beam cranes)

As an indispensable equipment in industrial production, the safe and efficient operation of the electric hoist (single-beam crane) of the bridge crane is directly related to the smoothness of the production line and the safety of personnel. With its unique single-beam structure and electric hoist lifting system, this equipment plays an important role in the handling of various heavy materials. In order to ensure the stability and safety of the electric hoist of the bridge crane during operation, it is particularly important to formulate a set of detailed and easy-to-operate operating procedures. This procedure not only covers the preparations and inspections before operation, but also details the operating steps and specifications, as well as safety precautions and risk prevention and control measures, aiming to help operators fully understand and master the use of the equipment, ensure that each lifting operation can proceed smoothly, and minimize potential safety risks.

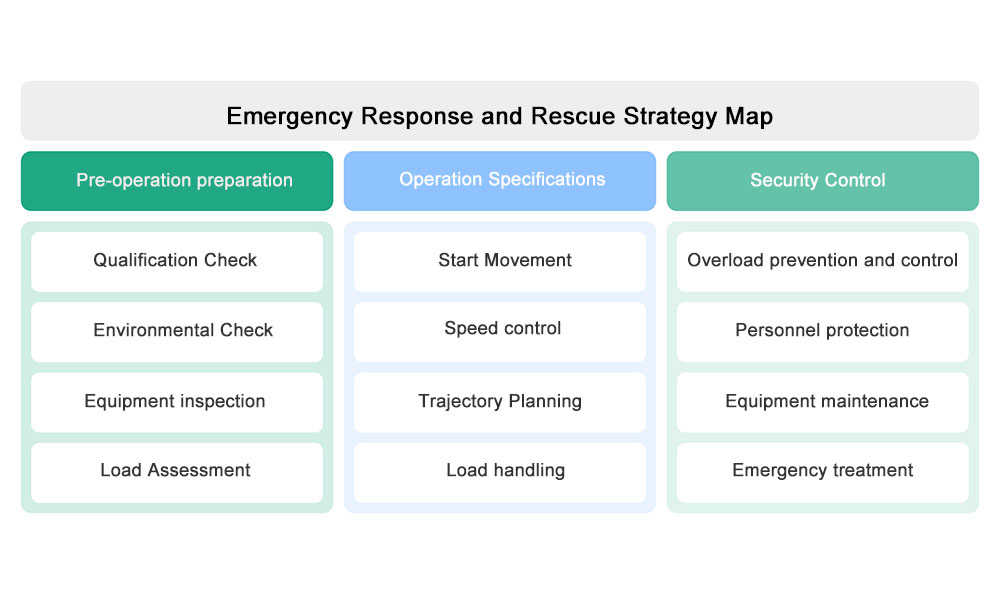

Pre-operation preparation and inspection

Before operating the key equipment of the electric hoist of the bridge crane, a series of detailed and meticulous preparations and inspections are required to ensure the safety, efficiency and smooth progress of the entire operation process.

Operator qualifications and requirements

Operators must hold a valid professional operation certificate and pass a strict training and assessment procedure to ensure that they have a deep understanding and proficiency in the structural design, performance parameters, operating procedures and maintenance knowledge of the electric hoist of the bridge crane. In addition, operators must also have good physical condition, including but not limited to vision, hearing, reaction ability, etc., to ensure that they can quickly make correct judgments and take effective measures in an emergency. It is strictly forbidden to work under the influence of alcohol or fatigue to ensure the concentration and accuracy of the operation process.

Equipment appearance and structural inspection

Before each operation, the operator should conduct a comprehensive appearance inspection of the electric hoist. This includes but is not limited to: checking whether the hoist shell is intact, whether there are any bumps or severe wear; whether fasteners such as bolts and nuts are loose or missing, affecting the overall stability of the equipment; for key components such as wire ropes, it is necessary to check whether there are defects such as wear, deformation or cracks on the surface; whether the pulley is in good operating condition, whether the hook is firm and reliable, and whether the connection between the components is tight and reliable. If any abnormal phenomenon is found, the operation should be stopped immediately and a detailed report should be made so that maintenance measures can be taken in time.

Electrical system and safety device inspection

The inspection of the electrical system is the key to ensure the safe operation of the equipment. The operator should check whether the power line is intact, whether the terminal is tight and reliable, whether the control switch is sensitive and effective, and whether the protection devices such as overload protection and short circuit protection are complete and working properly. It is also necessary to test the safety devices such as limiters and emergency stop switches to ensure their sensitivity and effectiveness. The limiter should be able to accurately limit the operating range of the equipment to avoid accidents caused by overload or misoperation; the emergency stop switch should be able to quickly cut off the power supply in an emergency to ensure that the equipment stops running immediately.

Electrical System and Safety Devices Checklist

| Inspection items | Inspection content | Inspection criteria | Inspection results |

| Power line | Visual inspection | Intact, no exposure or damage | _ |

| Wiring terminal | Fastening condition | Reliable fastening without looseness | _ |

| Control switch | Functional Testing | Sensitive and effective, correct operation | _ |

| Protection device | Integrity check | Overload protection, short circuit protection, etc. are complete and work normally | _ |

| Limiter | Functional Testing | Ability to accurately limit the operating range of equipment | _ |

| Emergency stop switch | Functional testing | Ability to quickly cut off power in an emergency | _ |

| Indicator lights and alarm devices | Status Check | The indicator light is on normally and the alarm device is effective | _ |

| Grounding device | Security Check | Good grounding, no looseness or corrosion | _ |

Pre-operation preparation and inspection overview

| Inspection Category | Inspection items | Precautions |

| Personnel Qualification | Operation certificate | Must hold a valid certificate |

| Personnel status | Physical conditions | Good vision, hearing and reaction ability. Do not work while drunk or tired. |

| Equipment Appearance | Hoist shell | Completely intact, with no signs of damage or severe wear and tear |

| Fasteners | Bolts, nuts, etc. are reliably fastened, without loosening or missing | |

| Key components | The wire rope, pulley, hook, etc. are free of wear, deformation or cracks | |

| Electrical system | Power line | Intact, the wiring terminals are securely fastened |

| Control switch | Sensitive and effective, protection devices are complete and working properly | |

| Safety devices | Limiter | Accurately limit the operating range of equipment |

| Emergency stop switch | Cut off the power supply immediately in an emergency | |

| Lifting load | Weight Assessment | Not exceeding the rated lifting capacity of the electric hoist |

| Work Environment | Ground conditions | Flat and obstacle-free, with sufficient space height |

| Environmental factors | Consider the impact of wind, temperature, humidity, etc. on operations |

Lifting load and working environment assessment

Before operation, the operator should make an accurate weight assessment of the goods to be hoisted to ensure that the rated lifting capacity of the electric hoist is not exceeded. At the same time, conduct a comprehensive assessment and inspection of the working environment: check whether the ground is flat and whether there are obstacles or other potential hazards; confirm whether the space height of the working area is sufficient to avoid collisions during hoisting; assess the location and number of obstacles around the goods in order to plan a reasonable working path; understand the environmental conditions of the working site, such as wind, temperature, humidity and other factors, which may affect the operation.

Operation steps and specifications

Starting and running operations

Before starting the electric hoist, the operator must ensure that all preparations have been completed. This includes checking whether the equipment is intact, whether the power is connected, whether the hook and hoisting accessories are firm and reliable, etc. After confirming that the preparations are completed, the operator should strictly follow the operating procedures to start and run the electric hoist.

First turn on the power to ensure that the power supply is stable and reliable. Then press the start button to start the hoist slowly and run smoothly. During operation, the operator should always pay attention to the operating status of the equipment, observe whether the equipment is operating normally, whether there are abnormal sounds or vibrations, etc. If the equipment is found to be operating abnormally, it should be stopped immediately and inspected and repaired. At the same time, the operator should adjust the operating speed in time to ensure smooth and safe operation. During operation, avoid excessive acceleration or deceleration to reduce the impact and wear on the equipment.

Load lifting and moving operation

When lifting the load, the operator needs to ensure that the hook and the load are firmly and reliably connected. When connecting the hook and the load, special lifting equipment must be used and ensure that the lifting equipment is intact. The operator should also check whether the connection between the hook and the load is firm and reliable to avoid the load from slipping or tilting. When moving the load, the electric hoist should be operated slowly and smoothly. Avoid sharp acceleration or deceleration to reduce the impact and wear on the equipment. At the same time, the operator needs to always pay attention to the movement trajectory of the load. During the movement, collision with obstacles should be avoided to ensure the safety of the operation.

Operation guide for special situations

When encountering special situations, such as excessive load, equipment failure or sudden changes in the working environment, the operator should remain calm and operate according to the emergency plan. When encountering excessive load, the operator should first confirm whether the weight of the load is within the load range of the equipment. If it exceeds the load range of the equipment, the operation should be stopped immediately, and inspection and processing should be carried out. When encountering equipment failure, the operator should stop the operation immediately and cut off the power supply. Then check and repair the equipment to ensure that the fault is eliminated before operating. When encountering sudden changes in the working environment, the operator should adjust the operation plan according to the actual situation. If the operation plan needs to be adjusted, the operation should be stopped first, and sufficient analysis and discussion should be carried out. At the same time, communication and coordination should be carried out with relevant departments to ensure that the operation is carried out safely and smoothly.

Shutdown and power-off operation

After the operation is completed, the operator should perform the shutdown and power-off operation of the electric hoist in accordance with the operating procedures. First turn off the control switch of the electric hoist, and then cut off the power supply. After cutting off the power supply, the equipment needs to be fully inspected and maintained. Check whether the various components of the equipment are intact and whether there are any abnormal conditions. At the same time, record the homework situation including homework time, homework content, homework results, etc. to prepare for the next homework.

Safety precautions and risk prevention and control

Overloading and eccentric loading risk prevention and control

Overloading and eccentric loading are common safety hazards in the operation of electric hoists of bridge cranes. In order to ensure the safety of the operation, the operator should strictly abide by the rated lifting capacity of the equipment and avoid overloading. When hoisting the load, the operator needs to fully understand the distribution of the load, ensure that the load is evenly distributed, and avoid the occurrence of eccentric loading.

Maintaining a safe distance between personnel and equipment

During the operation, the operator must always maintain a safe distance from the equipment. When the equipment is running, the operator should stay away from the operating area of the equipment to avoid being hit by the equipment or load. At the same time, the operator must also ensure that other personnel are not in the operating area to avoid accidents. To further improve safety, obvious warning signs and isolation facilities can be set up in the operating area to remind other personnel to keep a safe distance.

Safety measures to prevent collision and entanglement

In order to effectively prevent the electric hoist from colliding with surrounding obstacles, the operator must plan the operation path in detail in advance to ensure that the equipment runs on a safe track. At the same time, key components such as wire ropes and pulleys must be regularly inspected to ensure that these components will not be entangled or knotted during use, thereby ensuring the safety of the operation.

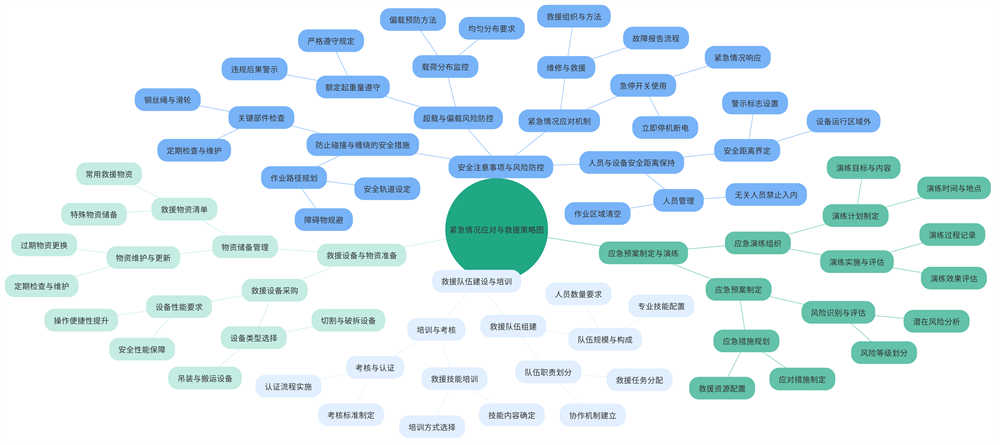

Emergency response and rescue

During the operation, in case of an emergency, the operator must immediately press the emergency stop switch, shut down the machine and cut off the power. If the equipment fails or an abnormal situation occurs, the operator should immediately stop the operation and notify the relevant personnel for maintenance. At the same time, if a safety accident or emergency occurs during the operation, the operator should quickly organize personnel for rescue to ensure the safety of personnel and equipment. In order to improve emergency response capabilities, enterprises should regularly organize emergency drills to enhance the emergency response capabilities of operators. Through drills, operators can become familiar with emergency response processes and methods and improve their ability to respond to emergencies.

Equipment maintenance and care

Regular cleaning and lubrication of electric hoists is the key to keeping them in good operating condition. Operators need to regularly clean the dust and oil on the surface of the equipment to ensure that the equipment is clean. At the same time, it is also necessary to lubricate the pulleys, bearings and other parts to reduce wear and friction and extend the service life of the equipment.

Regular comprehensive inspection and maintenance of electric hoists is the guarantee for their safe operation. This includes checking whether the electrical system, mechanical parts, safety devices, etc. are intact, and timely repairing or replacing any faults or hidden dangers found. At the same time, it is also necessary to record and analyze the operating data of the equipment so as to detect potential problems in time and take measures.

With the increase of usage time, the key components of the electric hoist may wear or age. To ensure the stable performance of the equipment, operators need to regularly inspect and replace these components. At the same time, according to production needs and technological development, the equipment should be upgraded and transformed in a timely manner to improve operating efficiency and safety.

Establishing a complete equipment maintenance and maintenance file is an important means to ensure the standardization of equipment management. Operators need to record each maintenance and maintenance, including maintenance time, content, replacement parts and other information. These records not only help track the status of the equipment, but also provide a reference for subsequent repairs and maintenance.

In summary, the operating procedures of the electric hoist of the bridge crane (single beam crane) cover many aspects such as pre-operation preparation, operating steps, safety precautions and risk prevention and control, and equipment maintenance and maintenance. Strict compliance with these procedures is of great significance to ensure production safety and improve work efficiency. Enterprises should strengthen the training and management of operators to ensure that the procedures are effectively implemented.