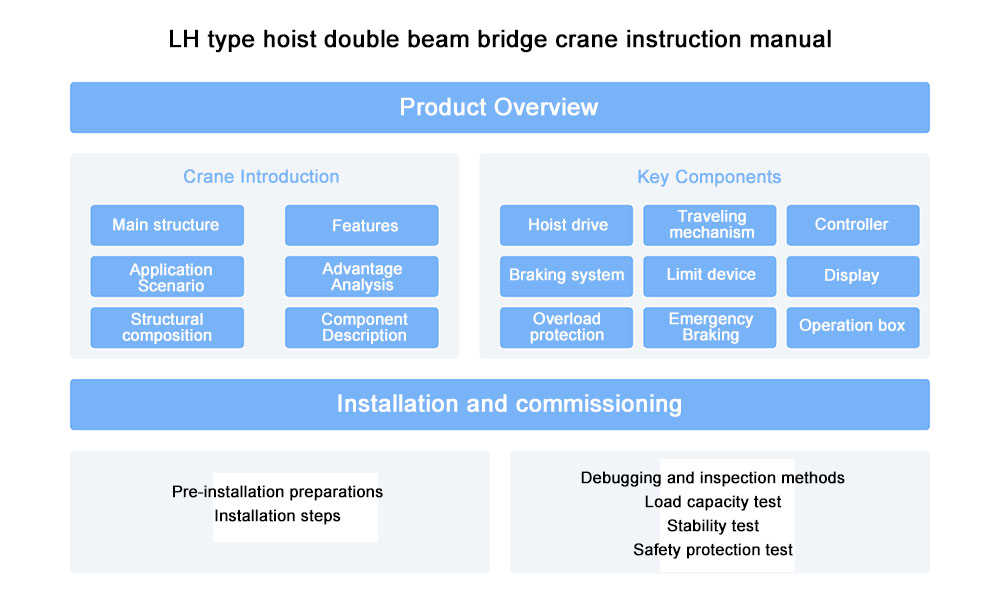

LH type hoist double beam bridge crane instruction manual

LH type hoist double girder bridge crane, as an indispensable lifting equipment in the modern industrial field, is widely praised for its efficient and stable performance. This crane not only integrates advanced design concepts and manufacturing processes, but also achieves a comprehensive upgrade in function to meet the diverse and complex operation needs. From the handling of heavy materials to the lifting of precision components, the LH type hoist double girder bridge crane can complete various tasks with ease. This instruction manual aims to comprehensively introduce the product characteristics, structural composition, installation and commissioning, operation procedures, maintenance and safety regulations of the crane, so as to help users quickly get started and give full play to its performance advantages. Through meticulous explanations and guidance, users will be able to use this equipment more safely and efficiently, providing strong support for production operations.

Product Overview

Introduction to LH type hoist double girder bridge crane

LH type hoist double girder bridge crane is a heavy lifting equipment designed for modern industrial production. The crane combines advanced manufacturing technology and precision component design to provide efficient and stable lifting solutions. Its excellent performance and excellent design enable it to perform well in various complex environments.

Main functional features

The LH type hoist double-beam bridge crane has a variety of functional features, such as precise lifting control, efficient work efficiency, strong load capacity and easy-to-maintain design. The crane adopts an advanced hoist drive system, which can achieve smooth lifting and movement, reducing vibration and noise during work. At the same time, the crane is also equipped with a variety of safety protection devices, such as limit switches, overload protection, anti-slip devices, etc., to ensure safety and reliability during operation.

Application scenarios and scope

The LH type hoist double-beam bridge crane is widely used in various places requiring heavy lifting operations, such as factory workshops, warehouses, docks, etc. It is suitable for lifting various heavy goods and equipment, such as mechanical equipment, steel, containers, etc. In addition, the crane can also be used for material handling and assembly operations on the production line, greatly improving production efficiency.

Product advantage analysis

Compared with other types of cranes, the LH type hoist double-beam bridge crane has significant advantages. Its double-beam structure provides higher strength and rigidity, allowing the crane to remain stable under heavy loads and high-speed operation. The hoist drive system of the crane adopts advanced transmission technology, making the operation of the crane more stable and efficient. In addition, its safety protection device can ensure the safety and reliability during operation. The crane is also easy to maintain and operate, which reduces the operating cost and maintenance difficulty.

Comparison table of LH type hoist double beam bridge crane and other models

| Model | Lifting capability | Structure type | Control method | Work efficiency | Safety protection device | Maintenance convenience |

| LH type hoist double girder overhead travelling crane | High load | Double beam structure | Advanced hoist drive | High efficiency | Perfect | Easy to maintain |

| Single girder overhead travelling crane | Medium load | Single beam structure | Traditional drive | General | Basic | General |

| Electric hoist crane | Low to medium load | Hoist hanging type | Electric control | Normally to efficient | Basic | General |

| Gantry crane | High load | Gate structure | Diversified control | High efficiency | Perfect | Complex |

| Jib crane | Low to medium load | Cantilever structure | Specific controls | General | Basic | General |

Detailed comparison parameters of LH type hoist double beam bridge crane

| Project | LH type hoist double girder overhead travelling crane | Comparison Model A | Comparison Model B |

| Lifting capability | High (the specific value depends on the model) | Moderate | Low to medium |

| Span range | Wide range of options | Limited scope | Limited scope |

| Lifting height | Customizable | Standard Height | Standard Height |

| Running speed | High-speed operation | Normal speed | Normal to high speed |

| Control method | Advanced hoist drive system | Traditional control method | Modern control system |

| Safety protection device | Limit switch, overload protection, etc. | Basic protection device | Complete protection device |

| Noise level | Low noise | General noise | High noise (some models) |

| Maintenance cost | Low (easy to maintain) | General | High (complex structures) |

| Applicable Scenarios | Heavy lifting workplaces | Medium load places | Light to medium duty locations |

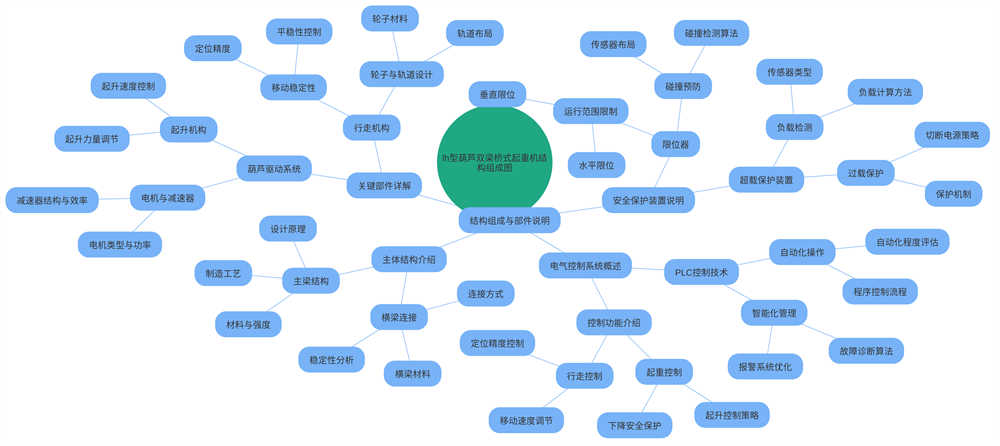

Structural composition and component description

Introduction to the main structure

The main structure of the LH type hoist double-beam bridge crane consists of two parallel main beams and a crossbeam connecting the two main beams. The main beam is made of high-strength steel, has excellent bending strength and rigidity, and can withstand large bending moments and loads. The crossbeam is used to connect and support the two main beams to ensure the overall stability of the crane.

Detailed explanation of key components

The key components of the LH type hoist double-beam bridge crane include the hoist drive system, travel mechanism, brake, etc. The hoist drive system adopts an advanced motor and reducer combination to achieve smooth lifting and movement. Among them, the motor provides power, and the reducer uses gear transmission to reduce speed and increase torque, so that the hoist drive system has sufficient lifting power. The travel mechanism is responsible for the movement of the crane on the main beam. It adopts wear-resistant wheels and track design to reduce friction and wear during operation. The travel mechanism can ensure that the crane moves smoothly on the main beam, thereby achieving accurate positioning and operation. The brake is used to stop the movement of the crane in an emergency to ensure the safety of operation. The brake can quickly and effectively stop the crane at the desired position to avoid accidents.

Safety protection device description

The LH type hoist double beam bridge crane is equipped with a variety of safety protection devices, including limiters, overload protection devices, emergency stop buttons, etc. The limiter is used to limit the operating range of the crane to prevent it from exceeding the safe area. The limiter can ensure that the crane operates within the safe range to avoid collision and damage. The overload protection device is used to detect the load of the crane. When the load exceeds the rated value, the power supply is automatically cut off to protect the crane from damage. The overload protection device can prevent the crane from being damaged due to overload and ensure its long-term stable operation. The emergency stop button is used to quickly stop the movement of the crane in an emergency. When an emergency occurs, the operator can quickly stop the movement of the crane by pressing the emergency stop button to avoid safety accidents.

Electrical control system overview

The electrical control system of the LH type hoist double beam bridge crane adopts advanced PLC control technology to realize automated and intelligent operation. The system has a variety of control functions, such as lifting control, travel control, safety protection, etc. Through PLC control technology, the crane can be operated automatically and intelligently to improve production efficiency. The system also has fault diagnosis and alarm functions, which can detect and handle faults in time to ensure the normal operation of the crane. When a fault occurs, the system will automatically diagnose and send out an alarm signal to remind the operator to handle the fault in time.

Installation and commissioning

Preparation before installation

Before installing the LH type hoist double beam bridge crane, a series of preparations need to be carried out. First, it is necessary to determine the installation location and track layout of the crane, taking into account factors such as the frequency of use of the crane, load-bearing requirements and working environment, to ensure that the crane can operate smoothly and use safely. Secondly, carefully check the various components of the crane to ensure that each component is intact and has the necessary strength and stability. At the same time, prepare the required installation tools and materials, including wrenches, screwdrivers, jacks, tracks, bolts, etc., and ensure that the quality of these tools and materials is reliable. Finally, formulate a detailed installation plan and safety measures, including installation steps, personnel division of labor, safety warnings, etc., to ensure the safety and smooth progress of the installation process.

Installation steps and process

The installation steps of the LH type hoist double beam bridge crane include track installation, main beam and cross beam assembly, hoist drive system and walking mechanism installation, etc. During the installation process, it is necessary to strictly follow the instructions of the installation manual to ensure the correct installation and commissioning of each component. First, it is necessary to install the track according to the design requirements and ensure that its horizontality and verticality meet the requirements. When installing the track, it is necessary to use tools such as a level and a plumb line to measure and adjust to ensure that the flatness and verticality of the track meet the requirements. Next, assemble the main beam and the crossbeam together, and install the hoist drive system and the travel mechanism. When assembling the main beam and the crossbeam, it is necessary to use bolts and other connectors to firmly connect them together, and ensure that the position and angle of each component meet the design requirements. Then, install the hoist drive system and the travel mechanism on the main beam and the crossbeam, and ensure that they operate normally. Finally, carry out various debugging work.

Debugging and inspection methods

After the installation is completed, the LH type hoist double beam bridge crane needs to be debugged and inspected. During the debugging process, it is necessary to test whether the various functions of the crane are normal, such as lifting control, travel control, safety protection, etc. At the same time, it is also necessary to test the load capacity and stability of the crane to ensure that it meets the design requirements. Inspection methods include visual inspection, measurement inspection, functional testing, etc. Visual inspection mainly inspects the appearance of the crane to check whether there is damage, deformation, etc. Measurement inspection mainly measures and inspects the size and accuracy of the crane. Functional testing mainly tests and verifies the various functions of the crane.

Installation precautions and requirements

When installing the LH type hoist double beam bridge crane, the following points need to be noted: First, it is necessary to ensure the safety of personnel during the installation process and take necessary safety measures and protective measures. During the installation process, relevant safety regulations and operating procedures must be followed to ensure the safety of personnel and property. Secondly, it is necessary to strictly follow the instructions of the installation manual to ensure the correct installation and commissioning of each component. During the installation process, the relevant contents of the installation manual must be carefully read and operated as required. Finally, after the installation is completed, the crane needs to be fully inspected and tested to ensure its normal operation and safety. Through the above introduction and analysis of preparations, installation steps, commissioning and inspection methods, and precautions, it can be seen that in the actual operation process, we need to strictly follow the relevant requirements and take necessary safety measures to ensure the safety of personnel and the normal operation and service life of the equipment.

Operation Guide

Power-on and Start-up Operation

Before starting the LH type hoist double-beam bridge crane, a series of preparations need to be carried out. First, the operator needs to carefully check the various components of the crane to ensure that they are all in normal condition. This includes key components such as the hoist drive system, walking mechanism, brakes, and lifting tools such as hooks and slings. After completing the inspection, turn on the power and start the crane according to the instructions in the operation manual. During the startup process, the operator needs to pay attention to observe whether the operating status and indicator lights of the crane are normal to ensure that the crane can operate normally.

Lifting operation process

The lifting operation process of the LH type hoist double-beam bridge crane includes steps such as lifting, moving, and positioning. First, select appropriate slings and slings according to the weight and size of the cargo to ensure that the cargo can be lifted safely and reliably. Then, by controlling the hoist drive system, the lifting and moving of the cargo is achieved. During the movement process, the operator needs to pay attention to observe the operating status and surrounding environment of the crane to ensure safety. When the cargo arrives at the designated location, position the cargo to the designated location and put it down.

Emergency handling measures

During the operation of the LH type hoist double beam bridge crane, you may encounter emergency situations, such as power failure, equipment failure, etc. At this time, emergency measures need to be taken to deal with it. First, you need to press the emergency stop button immediately to cut off the power supply to protect the safety of equipment and personnel. Then, take corresponding handling measures according to the fault situation, such as contacting maintenance personnel for inspection and repair. Before waiting for the maintenance personnel to arrive, the operator can take necessary measures to ensure the safety of the site.

Daily operation precautions

In the daily operation of the LH type hoist double beam bridge crane, you need to pay attention to the following points: First, you need to keep the crane clean and tidy to avoid the influence of debris and dust on the equipment. Secondly, you need to regularly check whether the various components of the crane are in normal condition, such as the hoist drive system, walking mechanism, brakes, etc. Finally, you need to follow the instructions of the operation manual during operation to ensure safe operation. In addition, operators need to be trained regularly to improve their skill level and safety awareness.

Maintenance and care

Daily maintenance and care requirements

For LH type hoist double beam bridge crane, daily maintenance and care work is the basis for ensuring stable operation of equipment, improving work efficiency and extending service life. In daily maintenance and care, meticulous attention and care are paid to each key component of the crane. First of all, the hoist drive system is regularly inspected, including whether the drive device is operating normally, whether the transmission parts such as gears and chains are severely worn, and whether the lubrication is in good condition. For the walking mechanism, it is necessary to ensure that the clearance between the wheels and the rails is reasonable, and there is no phenomenon of being too large or too small. At the same time, check the wear condition of the walking wheel and the reliability of the brake device. As a key component to ensure the safe operation of the crane, the maintenance of the brake is particularly important. It is necessary to regularly check the wear of the brake pads, whether the working pressure of the brake hydraulic system is normal, and whether the brake response time meets the requirements.

In addition to the inspection of the above mechanical components, the normal operation of the electrical control system is also crucial. Electrical components such as contactors and relays should be regularly tested for problems such as ablation and aging; control and signal lines should be carefully checked to ensure that the lines are firmly connected, undamaged, and have good insulation performance; for cranes equipped with automatic control systems, attention should also be paid to software updates, parameter settings, and data backup.

During daily maintenance, operators are also required to strictly follow the guidelines in the equipment manual and do regular cleaning. Keep the equipment body and working environment clean and tidy to avoid equipment performance degradation or safety accidents caused by dust and water accumulation. At the same time, for key components that are susceptible to environmental influences, such as electrical control systems and precision mechanical components, necessary dust and water prevention measures should be taken.

Regular maintenance plan

In order to ensure the normal operation and extend the service life of the LH type hoist double-beam bridge crane, a regular maintenance plan needs to be formulated. The plan should cover the following key aspects:

- Regular inspection: According to the frequency of equipment use and working conditions, the inspection cycle should be reasonably arranged, such as a comprehensive inspection every week, month, or quarter. The inspection content should include but not be limited to the wear, deformation, damage, looseness and falling of each component; wear measurement and replacement of wearing parts such as pins, bearings, seals, etc.

- Cleaning and lubrication: Keep the inside and outside of the equipment clean, and regularly remove dust, debris and oil stains. Provide sufficient and appropriate lubrication for all rotating parts and friction pairs to reduce wear and reduce energy consumption. Replace new oil or clean in time according to the lubrication chart and oil change cycle regulations.

- Replace wearing parts: Predict in advance and replace related parts in time according to the wearing parts life table and actual wear conditions, such as brake pads, wire ropes, cables and other wearing parts.

- Record management: Establish a complete maintenance record system, and record in detail the specific content and results of each inspection, repair, and replacement of parts, so as to analyze the equipment condition trend and promptly discover and deal with potential problems.

When implementing the regular maintenance plan, the specific requirements of the equipment maintenance manual must be strictly followed to ensure that all operating specifications are accurate. At the same time, problems and potential faults found should be dealt with in a timely manner to prevent small problems from turning into major faults.

Common fault troubleshooting and solutions

LH type hoist double beam bridge crane may encounter various fault conditions during use, such as hoist drive system failure, walking mechanism failure, etc. In the face of these faults, scientific and effective troubleshooting and solutions need to be adopted to deal with them:

- Fault observation and preliminary judgment: When the crane has abnormal sound, abnormal display or functional failure, it should be immediately taken seriously and preliminary observation and judgment should be made. According to the fault phenomenon combined with the corresponding fault code, the location and possible cause of the fault should be determined as accurately as possible.

- Fault replication and confirmation: Try to repeat the fault phenomenon and carefully check all components related to the fault, such as drive device, brake, sensor, etc. Through the replication and careful observation of the fault phenomenon, further verify the preliminary judgment result.

- Fault troubleshooting manual guidance: Refer to the troubleshooting process and methodology in the technical manual and maintenance guide provided by the crane manufacturer for detailed troubleshooting. According to different fault types and machine characteristics, gradually and deeply check the status of each subsystem and component.

- Fault repair and adjustment: Repair the fault points found and replace damaged parts according to the results of the troubleshooting; take temporary measures to ensure the safe operation of the equipment for parts or system problems that cannot be repaired immediately, and purchase spare parts for replacement in time; make necessary parameter adjustments after the repair is completed to ensure that the performance of the whole machine returns to normal levels.

- Record summary and improvement: Record the process, methods, results and replacement parts of each troubleshooting in detail to form a complete fault handling file. By analyzing and summarizing the rules of the archive data, find out potential equipment problems and management loopholes, continuously optimize maintenance strategies and improve equipment operating environment conditions.

Be sure to follow the principle of safety first throughout the troubleshooting and resolution process! Comply with the corresponding safety operating procedures and protective measures; consult professionals or contact manufacturers for technical support in a timely manner for uncertain or risky links.

Comparison table of common faults and solutions of LH type hoist double beam bridge crane

| Fault Type | Fault manifestation | Possible Causes | Solution |

| Hoist drive failure | Abnormal sound, unable to start | Gear wear, chain looseness, motor failure | Check and replace worn parts, check motor condition and repair or replace |

| Traveling mechanism failure | Wheel jamming, track deviation | Unreasonable clearance, wear of travel wheels, failure of brake device | Adjust the clearance, replace worn wheels, check and repair the brakes |

| Brake failure | Brake failure, slow braking | Brake pads worn, hydraulic system pressure insufficient | Replace brake pads, check and adjust hydraulic system pressure |

| Electrical control failure | Contactor burnout, poor line connection | Component aging and circuit damage | Replace aging components, check and repair line connections |

| Display abnormality | The display is black or has garbled characters | 电源故障、软件问题 | Check power status, update or repair software |

Key points for maintenance of LH type hoist double beam bridge crane

| Maintenance category | Key points | Cycle recommendation | Precautions |

| Regular inspections | Wear, deformation and looseness of each component | Weekly/Monthly/Quarterly | Meticulous inspection, timely recording and handling of identified problems |

| Cleaning and lubrication | Remove dust and oil, and provide suitable lubrication | According to the lubrication chart and oil change cycle | Keep the equipment clean inside and outside and ensure lubrication is in place |

| Replace wearing parts | Brake pads, wire ropes, cables, etc. | Based on the life table of wearing parts and actual wear conditions | Predict and replace in time to ensure safe operation of equipment |

| Record Management | Maintenance record system | After each inspection/repair | Detailed records and analysis of equipment status trends |

| Safety measures | Before each maintenance | 每次维护保养前 | Strictly abide by safety operating procedures and protective measures |

Safety instructions for maintenance

When performing maintenance on LH type hoist double beam bridge crane, you need to pay attention to the following safety instructions:

- Safety measures and protection: Before starting any maintenance work, you must ensure that the equipment is in a safe state and the power supply has been cut off. Wear complete personal protective equipment (such as helmets, gloves, protective glasses, etc.) in accordance with the operating procedures to prevent the risk of injury caused by accidental operation or falling parts.

- Follow the instructions of the manual: When performing maintenance, you must strictly follow the regulations and requirements in the equipment instruction manual and maintenance manual. For uncertain operating steps or maintenance items, you should consult the manufacturer or professional technicians in time for guidance and confirmation before implementing them.

- Operation status observation: During the maintenance process, always pay attention to the operating status of the crane and changes in the surrounding environment. In situations where multiple equipment are working together, ensure that the machines maintain a safe distance and avoid mutual interference; when working in a small space or complex environment, you must be more vigilant to prevent accidents such as bumps and squeezing.

Safety regulations and precautions

Safety operating procedures

In order to ensure the safe, effective and reliable operation of the LH type hoist double beam bridge crane, a set of detailed and rigorous safety operating procedures must be established. This set of procedures not only covers the meticulous preparations before operation, but also includes the key precautions during operation and the rapid and reasonable response measures in the face of emergencies. In the pre-operation preparation stage, every step is crucial, such as checking whether the structural components of the hoist double beam bridge crane are intact, whether the electrical control system is normal, and whether the lubrication system is sufficient. At the same time, it is necessary to ensure that the operator has a clear understanding of the working environment, including checking the flatness of the ground, clearing obstacles, and unobstructed safe passages.

During the operation, every step of the safety operating procedures must be strictly followed. For example, during hoisting operations, it is necessary to accurately calculate and set reasonable lifting heights, speeds and angles to avoid safety hazards caused by overloading, overheight or rapid movement. The selection and fixing methods of the binding ropes should be strictly followed in accordance with the regulations to prevent accidents caused by cargo falling off or slipping. In the face of emergencies, such as sudden power outages, equipment failures, or cargo falling, operators should quickly activate the preset emergency plan and perform standardized operations in accordance with the regulations to minimize potential losses.

Operator qualification requirements

As an efficient and precise lifting equipment, the safe operation of the LH type hoist double-beam bridge crane places extremely high professional requirements on operators. First of all, operators must receive systematic and comprehensive professional training, and have a deep understanding and mastery of the basic principles, structural characteristics, performance parameters and operating skills of the crane. This includes but is not limited to the operation methods of various functional components, such as the coordinated control of hook lifting, trolley operation, and trolley travel, as well as the correct understanding and maintenance knowledge of hydraulic and electrical systems. Through strict assessment and review, operators need to obtain relevant nationally recognized professional qualification certificates or operation certificates issued by manufacturers to ensure that they have qualified skills.

In addition to holding a valid certificate, practical operating experience is essential to ensure safety. Experienced operators can accurately judge the safety standards under various working conditions and prevent potential risks. For example, when working in a narrow space, they can flexibly adjust the lifting plan to avoid obstacles; when faced with emergencies such as cargo falling off or equipment failure, they can respond calmly and take effective emergency measures. In addition, good safety awareness is an essential quality for every operator, including risk assessment of the working environment, correct use of personal protective equipment, and strict compliance with various safety regulations and rules. Only in this way can we maximize the performance advantages of the LH type hoist double-beam bridge crane and improve work efficiency while ensuring our own safety.

Safety warning sign description

The LH type hoist double-beam bridge crane has a humanized design, and a variety of safety warning signs are set in prominent positions on the fuselage, aiming to remind and guide operators to strictly implement safety operating procedures and ensure the safe and orderly operation of the operation process. These signs are systematic and clear in meaning, covering types such as prohibition signs, warning signs, and instruction signs. Prohibition signs such as “No Passage” and “No Stay” clearly instruct operators not to enter or stay in dangerous areas in violation of regulations; warning signs are early warnings of possible risks, such as “Beware of Falling Objects” and “Anti-Slip Warning”; and instruction signs are direct instructions for correct operating methods, such as “Correctly Connect the Power Supply” and “Follow This Procedure”.

Operators must fully understand and master the meaning and purpose of these safety warning signs, and strictly abide by the corresponding safety requirements and precautions before and during the operation. This not only helps prevent safety accidents, but also significantly improves work efficiency and equipment life. At the same time, regular inspection and maintenance of signs to ensure that they are clear and functional is also an indispensable part of the operator’s responsibilities.

Environmental protection and energy-saving requirements

In modern manufacturing, environmental protection and energy conservation and emission reduction have become important indicators for measuring corporate social responsibility and sustainable development. For lifting equipment such as LH-type hoist double-beam bridge cranes, it is crucial to strictly follow the principles of environmental protection and energy conservation in actual application scenarios. First of all, we start from noise control and emission pollution, and effectively reduce the noise pollution generated during the operation of the crane by optimizing the design, selecting low-noise components and coordinating a reasonable lubrication system. Secondly, we focus on optimizing the operation efficiency and improving the load mode – scientifically planning the operation route to reduce the invalid moving distance; reasonably selecting the load scheme to save energy consumption.

The concept of environmental protection and energy saving should also be reflected in the maintenance link – try to use environmentally friendly materials and technical means for maintenance and renovation; establish a complete equipment status monitoring and fault warning system to timely detect problems and perform preventive maintenance; encourage employees to actively participate in equipment energy-saving transformation projects to achieve the goal of continuous cost reduction and efficiency improvement.

Accessories and accessories

List and description of standard accessories

The LH type hoist double girder bridge crane is equipped with the following standard accessories to meet basic use needs:

- Spreader: used to lift and carry goods of various shapes and sizes. Choose the appropriate spreader according to the weight and size of the goods, such as single-beam spreader, double-beam spreader, etc.

- Sling: bear the weight of the goods, connect the spreader and the hoist, and ensure the stability and safety of the goods during handling. Choose the appropriate sling according to the weight and size of the goods, such as wire rope, chain, etc.

- Remote control: the main tool for operating the crane, which can realize the lifting, lowering, forward and backward movements of the hoist. When using the remote control, make sure that the operator has received relevant training and follows the instructions in the operating manual for correct operation.

- Other accessories: such as buffers, dust covers, etc., are used to protect the structural components and operating components of the crane and improve service life and safety.

Optional accessories and purchase guide

In addition to standard accessories, the LH type hoist double girder bridge crane also provides a series of optional accessories that can further enhance the safety and reliability of the crane. When purchasing these accessories, users need to choose according to actual needs and budget. The following are some common optional accessories and their purchase guide:

- Limiter: used to limit the operating range of the crane to prevent accidental collision and damage. The operating distance and accuracy requirements of the crane need to be considered when purchasing.

- Overload protection device: When the weight of the cargo exceeds the rated load of the crane, the crane will automatically stop running to prevent overloading accidents. The weight of the cargo and the rated load of the crane need to be considered when purchasing.

- Anti-collision device: used to prevent the crane from colliding with other equipment or buildings to protect the safety of equipment and buildings. The operating environment and possible collisions of the crane need to be considered when purchasing.

- Protective cover: used to protect the electrical system and operating parts of the crane to prevent accidental contact and damage. The use environment and protection requirements of the crane need to be considered when purchasing.

- Other accessories: such as lubrication system, hydraulic system, etc., used to improve the performance and service life of the crane. The use requirements and budget of the crane need to be considered when purchasing.

Accessory replacement and installation method

During the use of LH type hoist double beam bridge crane, it may encounter accessories that are damaged or need to be replaced. At this time, it is necessary to take appropriate measures to replace and install accessories. The following are the general steps for accessory replacement and installation:

- Safety measures: Before replacing any accessories, the power of the crane must be turned off and the main power must be disconnected to prevent injury caused by accidental startup. At the same time, ensure that warning signs are set up in the work area and operated by qualified personnel.

- Remove damaged accessories: According to the disassembly manual of the structural components and operating components of the crane, find the disassembly method of the accessories that need to be replaced. Use appropriate tools and techniques for disassembly, while paying attention to protecting other components and surfaces from damage. Set aside the removed damaged accessories for further inspection and repair.

- Install new accessories: Place the new accessories in the position where they need to be installed. Use appropriate tools and techniques to fix and install according to the instructions in the disassembly manual. Make sure that the new accessories are installed in the correct position and are firmly and reliably connected to other components. Avoid excessive force or improper operation during installation that may cause damage to other components or surfaces.

- Inspection and testing: After completing the replacement of accessories, conduct a comprehensive inspection and test to ensure the normal operation and safety of the new accessories. Check whether the installation position of the new accessories is correct and whether the connection with other components is firm and reliable. Carry out relevant functional tests and performance checks, such as operating range, speed, load capacity, etc. Confirm whether the new accessories can meet the actual use requirements.

Technical parameters and performance indicators

Overview of main technical parameters

As a heavy lifting equipment widely used in modern industrial production, the design, manufacturing and application of LH type hoist double-beam bridge crane fully consider the diversity and complexity of actual working conditions. Its main technical parameters include lifting capacity, span, lifting height, working level, etc. These parameters not only determine the scope of application of the crane, but also directly affect its performance.

Lifting capacity is the core indicator for measuring the performance of the crane. It indicates the maximum weight that the crane can lift safely and effectively. The selection of this parameter is directly related to the design, manufacturing and use cost of the crane. If the selection is too small, the crane may be overloaded in actual work, thereby affecting the life of the equipment and may cause safety accidents; while if the selection is too large, it may cause waste of resources and reduce overall work efficiency. Therefore, it is crucial to select the appropriate lifting capacity according to actual needs and working conditions.

The span refers to the distance between the center lines of the crane track, which reflects the operating range of the crane in the horizontal plane. The size of the span depends on factors such as the demand for working space, the design of the building structure, and the weight and size of the cargo. When choosing the span, it is necessary to fully consider the needs of cargo transportation, loading and unloading, and storage to ensure that the crane can operate flexibly and efficiently during the operation.

Lifting height is an important indicator to measure the ability of a crane to lift cargo in the vertical direction. It indicates the maximum height to which the crane can safely and smoothly lift cargo under normal working conditions. The selection of this parameter is also based on actual operating requirements, including factors such as the size and weight of the cargo and the relative position of the loading and unloading platform. When purchasing, it is necessary to ensure that the selected lifting height can meet the highest requirements in the process of cargo loading and unloading and transportation.

The working level is a key parameter that reflects the frequency and service life of the crane. It is usually divided according to factors such as the use time of the crane, the load size, and the working environment. Cranes of different working levels are different in design, manufacturing, and use to meet the needs of different working conditions. Choosing the right working level can not only ensure the stable operation of the equipment, but also effectively save energy and cost investment.

In summary, the selection of the main technical parameters of the LH type hoist double-beam bridge crane is a process of comprehensive consideration of actual needs and working conditions. Only by making scientific and reasonable choices based on specific circumstances can we ensure that the crane has good performance and a long working life while meeting operational requirements.

Main technical parameters of LH type hoist double beam bridge crane

| Parameter name | Describe | Example/Scope | Influencing factors |

| Lifting capacity | The maximum weight that a crane can safely lift | _ | Design and manufacturing costs, working conditions, safety performance |

| Span | Distance between crane rail center lines | _ | Workspace requirements, building structure, cargo weight and dimensions |

| Lifting height | The maximum height to which a crane can safely lift cargo | _ | Cargo size, weight, loading platform location |

| Work level | Parameters that reflect the frequency of crane operation and service life | Divided by usage time, load size, and working environment | Stable equipment operation and energy cost investment |

LH type hoist double beam bridge crane performance index and evaluation analysis table

| Performance indicators | Describe | Evaluation method | Importance |

| Lifting efficiency | The ability to complete lifting operations per unit time | Evaluate actual operating speed and load capacity | The key to improving production efficiency |

| Smooth operation | Stability and comfort of the crane during movement | Involving aspects such as structural design and manufacturing accuracy | Ensure operation safety and improve operation comfort |

| Noise level | The size of the noise generated by the crane in the process of work | Evaluation using noise measuring instruments | Protect the working environment and the hearing health of employees |

| Energy consumption | Energy consumption of cranes during operation | Evaluation through energy consumption monitoring equipment | An important way to reduce energy costs and improve efficiency |

Performance indicators and evaluation analysis

The performance indicator system of LH type hoist double-beam bridge crane constitutes an important basis for comprehensively evaluating its comprehensive performance and use effect. These indicators cover multiple dimensions such as lifting efficiency, running stability, noise level and energy consumption. Through in-depth evaluation and analysis of these indicators, not only can the actual working performance of the crane be intuitively displayed, but also scientific guidance can be provided for the skill training of operators, and objective basis can be provided for the formulation and optimization of maintenance plans.

Lifting efficiency is an important performance indicator for evaluating the ability of LH type hoist double-beam bridge crane to complete lifting operations in unit time. This indicator directly reflects the operating speed and load capacity of the crane, which is of great significance for improving production efficiency; running stability is a key performance indicator for measuring the stability and comfort of the crane during movement. It involves many aspects such as the structural design and manufacturing accuracy of the crane; the noise level is an indicator that reflects the size of the noise generated by the crane during work. It is of great significance for protecting the working environment and the hearing health of employees; energy consumption is an indicator for measuring the energy consumption of the crane during work. With the continuous increase in energy costs, reducing energy consumption has become one of the important ways for modern industrial enterprises to reduce costs and improve efficiency. By evaluating and analyzing these performance indicators, we can understand the comprehensive performance and use effect of the crane, and provide a basis for optimizing operation and maintenance.

Load capacity and stability test

In order to ensure that the load capacity and stability of the LH type hoist double beam bridge crane meet the design requirements, load capacity and stability tests are required. During the test, it is necessary to simulate the actual working scene and load conditions in accordance with relevant standards and specifications, and perform lifting operations and operation tests on the crane. Through the test, the load capacity and stability performance of the crane can be evaluated, potential problems and deficiencies can be found, and corresponding measures can be taken to improve and optimize. At the same time, the test can also provide an important reference for the use and maintenance of the crane.