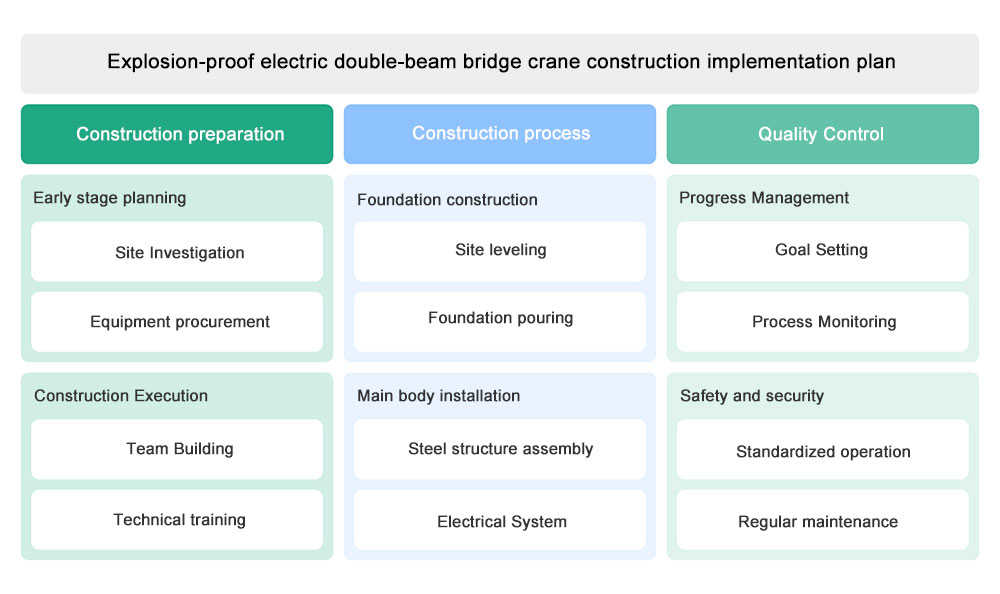

Explosion-proof electric double-beam bridge crane construction implementation plan

As an important equipment in modern industry, the safe and efficient construction and implementation of explosion-proof electric double-beam bridge crane is crucial to ensure production operations. This proposal aims to comprehensively explain the construction and implementation process of explosion-proof electric double-beam bridge crane, from project overview to construction preparation, to detailed construction plan and process management, to construction acceptance and post-maintenance, each step has been carefully designed to ensure the smooth progress of the project. Through scientific and reasonable planning, we aim to create a lifting system that meets safety standards and can operate efficiently, providing a solid guarantee for the safe production of enterprises.

Project Overview and Objectives

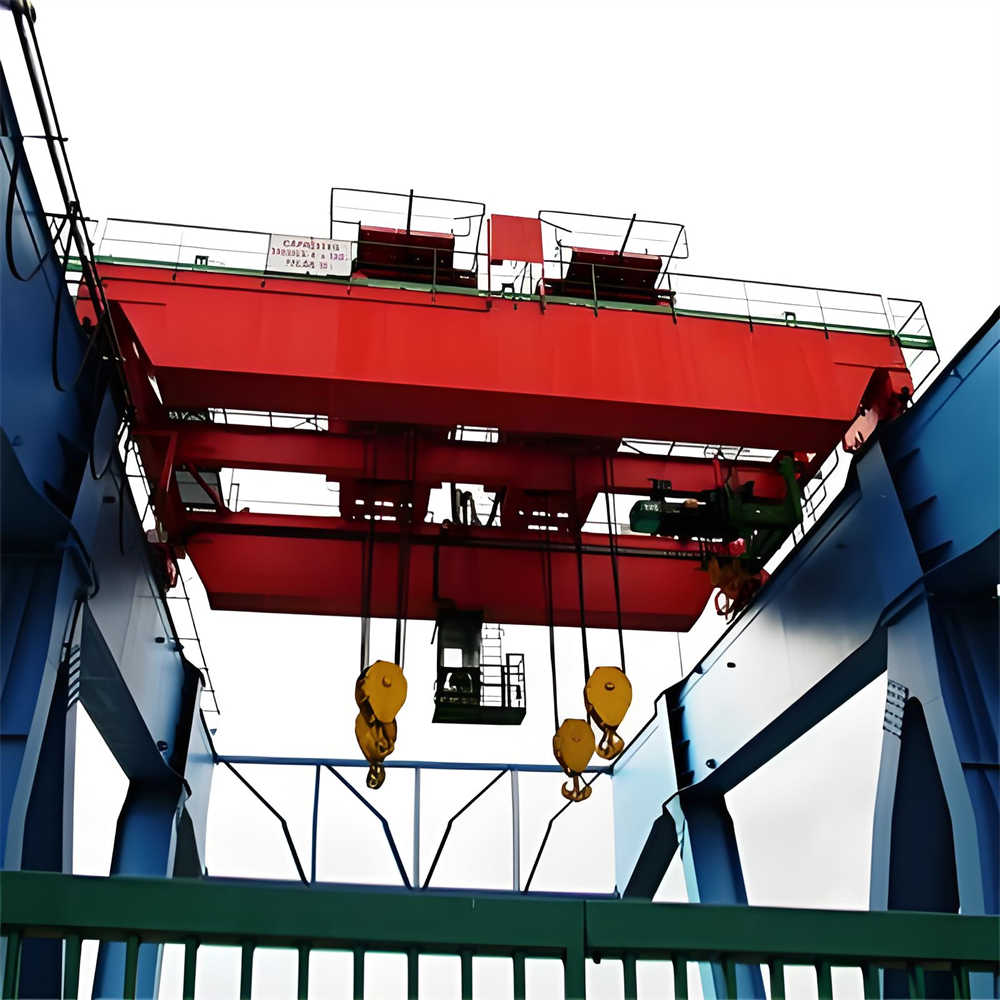

The main goal of this project is to install an explosion-proof electric double-beam bridge crane that is suitable for the special industrial environment of flammable and explosive material handling. In view of the particularity of the target environment, the design and manufacture of the crane must strictly follow the national and industry-related explosion-proof standards to ensure that during the hoisting operation, even in the face of flammable and explosive materials, it can effectively prevent potential safety risks caused by sparks, high temperatures or electrical sparks, and ensure the safety and stability of the working environment.

Specifically at the project implementation level, installation quality is the key to ensuring stable performance and safe operation of the crane. Therefore, the design blueprint must be followed accurately during the construction process to ensure the accuracy of the crane’s track installation, the electrical system wiring specifications, and the complete and normal configuration of explosion-proof equipment. At the same time, in order to improve the operating efficiency, the commissioning and testing of the crane is also an indispensable part. Through precise load tests, operating efficiency tests and other means, the crane can achieve the preset working efficiency under the premise of safety.

In addition, ensuring personnel safety is the basis of any industrial project. During the operation of the crane, it is necessary to equip personnel with professional training and operating certificates, and establish strict safety operating procedures, including but not limited to daily inspections, maintenance, emergency handling and other measures to ensure that the equipment is always in a safe and controllable state during operation to avoid any possible casualties.

In the long run, the success of the project is not only reflected in the smooth installation and commissioning of the explosion-proof electric double-beam bridge crane, but also in its subsequent long-term and stable operation. This means that from the moment the equipment is put into use, continuous monitoring and management are required, including regular maintenance, troubleshooting and repair, performance evaluation and optimization, etc., to ensure that it can maintain efficient, safe and stable operation throughout its service life, thereby providing strong support for the company’s production activities and creating long-term economic benefits and social value.

Project basic information table

| Project name | Explosion-proof electric double girder overhead travelling crane installation project |

| Project Objectives | Installation of explosion-proof electric double girder overhead cranes adapted to the handling of flammable and explosive materials |

| Design and Manufacturing Standards | National and industry-related explosion-proof standards |

| Key installation elements | Track installation accuracy, electrical system wiring specifications, explosion-proof equipment configuration |

| Debugging and testing content | Load test, operating performance test |

| Operator requirements | Have undergone professional training and hold an operation certificate |

| Safety operating procedures | Daily inspection, maintenance, emergency treatment, etc. |

| Long-term operation management | Regular maintenance, troubleshooting and repair, performance evaluation and optimization |

| Expected benefits | Provide efficient, safe and stable lifting operations, creating long-term economic benefits and social value |

Project Safety and Environmental Requirements Table

| Safety and environmental elements | Descriptive |

| Explosion-proof grade | Comply with national and industry explosion-proof standards |

| Installation environment | Special industrial environment for handling flammable and explosive materials |

| Personnel safety | Equipped with professionally trained and licensed operators, establish strict safety procedures |

| Explosion-proof measures | Prevent safety risks caused by sparks, high temperatures or electrical sparks |

| Equipment Monitoring and Management | Continuous monitoring, regular maintenance, troubleshooting and repair |

| Environmental protection | Ensure that the operation process does not cause additional risks or pollution to the environment |

| Emergency treatment | Establish an emergency response mechanism to deal with possible safety accidents |

| Compliance | Comply with all relevant laws and regulations and industry standards |

Pre-construction preparation

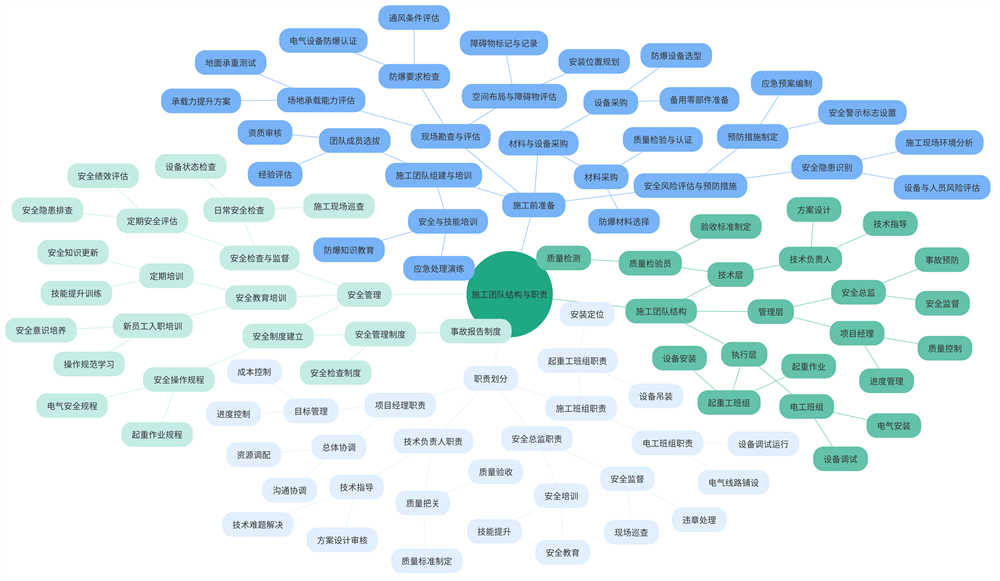

Site survey and evaluation

Before construction, a comprehensive survey of the installation site is required to evaluate the site’s bearing capacity, spatial layout, and potential obstacles. The assessor needs to carefully check the site’s bearing capacity to ensure that the ground bearing capacity of the installation site can meet the weight requirements of the crane. The spatial layout of the site also needs to be evaluated to ensure that the installation location of the crane can meet the requirements of its operation and operation. Possible obstacles, such as columns, walls, or other equipment, need to be marked and recorded so that they can be avoided during the design and installation process. It is also necessary to check whether the site meets the explosion-proof requirements, including ventilation conditions, electrical equipment layout, and possible fire sources. According to the survey results, a targeted transformation plan is formulated to ensure that the site environment meets the installation and operation requirements of the crane.

Construction team formation and training

Before construction, it is necessary to form a construction team with professional qualifications and rich experience, including crane operators, electricians, welders, etc. Strict training is carried out for construction team members to make them familiar with the structural characteristics, installation procedures and safety specifications of explosion-proof electric double-beam bridge cranes. The training content includes but is not limited to explosion-proof knowledge, safe operating procedures for lifting operations, emergency response measures, etc. Through training, it is ensured that the construction team members have the necessary knowledge and skills to complete the construction tasks safely and efficiently.

Materials and equipment procurement

According to the design specifications of the crane and the needs of the site, purchase materials and equipment that meet the explosion-proof requirements. This includes explosion-proof motors, explosion-proof electrical components, high-strength steel, etc. During the procurement process, it is necessary to ensure that the supplier has the corresponding qualifications and certifications, and to conduct strict inspections on the materials and equipment to ensure that their quality meets national standards and project requirements. In addition, a certain number of spare parts need to be purchased according to actual needs so that they can be repaired and replaced during subsequent use.

Safety risk assessment and preventive measures

Before construction, it is necessary to conduct a comprehensive assessment of the safety risks in the construction process to identify potential sources of danger and potential accidents. The assessor should carefully analyze the environment, equipment, personnel and other factors at the construction site to identify possible safety hazards. Based on the assessment results, formulate detailed preventive measures, such as setting safety warning signs, equipping personal protective equipment, and formulating emergency plans. In addition, a safety supervision mechanism needs to be established to ensure that various preventive measures are effectively implemented. Through comprehensive safety risk assessment and preventive measures, the risk of safety accidents in the construction process can be effectively reduced, and the safety of construction personnel and the smooth progress of the project can be guaranteed.

Detailed design of construction plan

Crane installation process

During the installation process of the crane, foundation construction is the first crucial step. This stage includes key links such as foundation treatment, embedded parts setting and foundation inspection. Foundation treatment needs to ensure that the ground is flat and solid and meets the design requirements, and embedded parts need to be precisely arranged to ensure the accuracy and stability of the crane installation. During the foundation construction stage, concrete pouring, curing and other operations are also required to ensure the strength and durability of the foundation. Next is the assembly of the steel structure, including the installation and welding of components such as columns, beams, and supports. At this stage, it is necessary to strictly abide by the installation specifications to ensure that the geometric dimensions, verticality, and flatness of the steel structure meet the design requirements. At the same time, anti-corrosion treatment and painting are also required to extend the service life of the steel structure. Finally, the electrical system is installed, including power lines, control lines, signal lines, etc. During the installation of the electrical system, it is necessary to strictly abide by the electrical safety regulations to ensure that the wiring of the electrical equipment is correct and the insulation is good. At the same time, the electrical system needs to be debugged and tested to ensure its normal operation. During the installation process, it is also necessary to pay attention to the coordination with other systems to ensure the overall installation progress and quality.

Implementation plan for explosion-proof measures

Develop a specific implementation plan for explosion-proof measures based on the explosion-proof level of the crane and the on-site environment. This includes the use of explosion-proof electrical equipment, the setting of explosion-proof isolation areas, and the control of fire sources. At the same time, explosion-proof measures should be regularly inspected and maintained to ensure their effectiveness. When operating in flammable and explosive places, relevant safety regulations and operating procedures must be strictly observed to ensure that explosion-proof measures are effectively implemented. It is necessary to strengthen the training and education of employees and improve their safety awareness and operating skills. Set up obvious safety warning signs and warning lights and other equipment on site to remind personnel to pay attention to safety. Measures such as reasonable arrangement of working hours and personnel rest time can also help improve work efficiency and safety.

Electrical system design and installation

Design electrical systems that meet explosion-proof requirements, including power lines, control lines, signal lines, etc. During the installation of the electrical system, electrical safety regulations must be strictly observed to ensure that the wiring of electrical equipment is correct and the insulation is good. At the same time, the electrical system must be debugged and tested to ensure its normal operation. In order to ensure the safe operation of the crane and the safety of personnel, it is necessary to attach great importance to the implementation of explosion-proof measures and the design and installation of electrical systems. During the design and installation process, we must fully consider the impact of factors such as the site environment and dangerous factors, as well as the skill level and safety awareness of the operators, and formulate detailed design plans and installation processes to ensure the stability and safety of the electrical system and cranes.

Quality control standards and inspection methods

Formulating strict quality control standards is a key link in ensuring the quality of crane installation. These standards should cover various aspects such as foundation construction, steel structure assembly, and electrical system installation. During the inspection process, a variety of methods should be used to conduct comprehensive inspections and record data, and rectify unqualified items to ensure that the installation quality of the crane meets the design requirements. At the same time, we must strengthen employee training and education, improve employees’ quality awareness and safety awareness, and ensure the stability and safety of the crane.

Crane installation quality control standard table

| Installation phase | Quality control standards | Inspection method |

| Foundation construction | The foundation is flat and solid, which meets the design requirements | On-site observation and measurement records |

| Embedded parts are precisely arranged and positioned | Check and measure dimensions against drawings | |

| Concrete pouring and curing meet standards | Strength test, curing time record | |

| Steel structure assembly | The geometric dimensions, verticality and flatness of the steel structure meet the design requirements | Instrument measurement, on-site observation |

| The welding quality meets the specifications, without defects such as cracks and slag inclusions | Weld inspection, non-destructive testing | |

| Anti-corrosion treatment and coating are uniform, without missing or peeling | Visual inspection, coating thickness measurement | |

| Electrical system installation | The electrical equipment is wired correctly and well insulated | Insulation resistance test, wiring check |

| The electrical system is debugged and tested normally without any faults. | Functional testing, operation records | |

| Explosion-proof measures are in place and comply with safety regulations | On-site inspection, explosion-proof level test |

Crane installation quality rectification measures table

| Non-conforming items | Corrective measures | Responsible Person |

| Uneven foundation | Re-process the foundation to ensure it is flat and solid | Basic construction manager |

| Position deviation of embedded parts | Adjust the position of embedded parts and re-fix them | Embedded parts installer |

| Steel structure size does not match | Correct the steel structure size and reassemble | Steel structure assembly manager |

| Unsatisfactory welding quality | Re-weld and perform non-destructive testing | Welding personnel, quality inspection personnel |

| Uneven anti-corrosion coating | Re-coating and re-coating to ensure uniform coating without missing any spots | Painting staff |

| Electrical wiring errors | Reconnect the wires to make sure they are connected correctly | Electrical installers |

| Electrical system failure | Troubleshoot and repair or replace faulty parts | Electrical commissioning personnel |

| Explosion-proof measures are not in place | Strengthen explosion-proof measures to ensure compliance with safety regulations | Explosion-proof measures implementers |

Construction process management

Progress management and adjustment

In construction process management, progress management is a crucial link. To ensure that the project is completed on time, a complete project progress management mechanism needs to be established. The mechanism should clarify the work objectives, time nodes and specific construction plans of each stage. During the construction process, the progress should be checked and evaluated regularly to promptly discover and resolve factors affecting the progress. At the same time, the progress should be adjusted and optimized according to the actual situation, such as adopting new technologies and improving construction efficiency to ensure that the project can be completed on time.

Safety supervision and accident prevention

Safety is the core element in the construction process. To ensure that various safety measures in the construction process are effectively implemented, it is necessary to strengthen safety supervision. Specific measures include: regular safety inspections of the construction site to promptly discover and eliminate safety hazards; establish an accident prevention mechanism, formulate emergency plans and rescue measures, and ensure rapid response and disposal when an accident occurs. In addition, safety education for construction personnel should be strengthened to improve their safety awareness and operational skills.

Establishment of communication and coordination mechanism

During the construction process, communication and coordination between all parties is crucial. To ensure that all parties in the project can communicate and work together in a timely manner, an effective communication and coordination mechanism needs to be established. Specific measures include: holding regular project meetings to report on project progress, discuss issues and seek solutions; strengthening communication with the owner and responding to their concerns and needs in a timely manner; establishing effective communication channels to ensure timely transmission of information and timely resolution of issues.

Implementation of environmental protection measures

During the construction process, it is the responsibility of every citizen and enterprise to strictly abide by environmental protection laws and regulations. To ensure the effective implementation of environmental protection measures, a series of specific environmental protection measures need to be taken. This includes controlling noise pollution, reducing dust, and properly disposing of waste. At the same time, environmental protection education for construction personnel should be strengthened to improve their environmental awareness and ensure that the impact on the environment during construction is minimized. In addition, environmental protection inspections should be carried out regularly on construction sites to promptly discover and correct environmental problems.

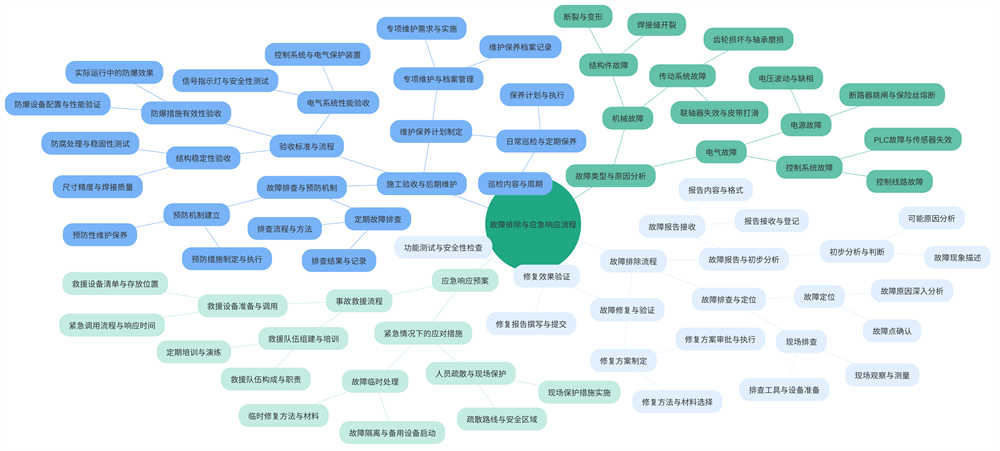

Construction acceptance and post-maintenance

Acceptance standards and processes

After the installation of the crane is completed, a set of detailed and scientific acceptance standards and processes must be formulated to ensure that the installation quality of the crane meets the design requirements and national standards. The acceptance work should cover several key aspects such as the structural stability of the crane, the performance of the electrical system, and the effectiveness of explosion-proof measures. The structural stability acceptance includes a comprehensive inspection of the dimensional accuracy, welding quality, and anti-corrosion treatment of the various components of the crane to ensure that its structure is complete, stable and reliable; the electrical system performance acceptance involves testing the control system, electrical protection devices, signal indicators, etc. of the crane to ensure that it operates normally, safely and reliably; the effectiveness of explosion-proof measures is for cranes used in flammable and explosive environments. It is necessary to verify whether the configuration of the explosion-proof equipment is reasonable, whether the performance meets the standards, and the effectiveness of the explosion-proof measures in actual operation.

During the acceptance process, the operation should be carried out strictly in accordance with the established standards and processes. The data for each acceptance content should be recorded in detail and a written acceptance report should be formed. At the same time, inviting the owner and experts in related fields to participate in the acceptance can not only ensure the fairness and authority of the acceptance results, but also further enhance the owner’s trust in the quality of the crane. Through strict acceptance procedures, potential problems can be discovered and solved in time, laying a solid foundation for subsequent safe operation.

Maintenance plan formulation

In order to ensure the long-term and stable operation of the crane, a comprehensive and thorough maintenance plan must be formulated. The plan should cover multiple levels such as daily inspections, regular maintenance, special maintenance, etc., and clearly stipulate the specific contents such as the lubrication cycle, tightening requirements, cleaning standards and replacement time of wearing parts of each component. The establishment of maintenance files is also very important. The time, content, and results of each maintenance should be recorded in detail to facilitate tracking the historical status of the equipment, analyzing the cause of the failure and summarizing the maintenance experience. Through regular maintenance, not only can the service life of the crane be extended, but also accidents caused by aging and wear of the equipment can be effectively prevented.

Troubleshooting and emergency response

For various types of failures that may occur during the operation of the crane, a complete troubleshooting mechanism should be established in advance. Once a failure occurs, the troubleshooting and repair process should be started immediately to restore the normal operation of the crane as soon as possible. At the same time, in order to reduce potential risks, an emergency response plan must be formulated, which should include detailed fault response measures, emergency operation steps, and accident rescue procedures. By strengthening the training of operators, their troubleshooting and emergency response capabilities can be improved. In addition, modern information technology means, such as remote monitoring systems and fault diagnosis software, can be used to achieve real-time monitoring and early warning of the crane’s operating status and prevent potential failures in a timely manner.

Project summary and feedback

Construction results summary

The construction results summary is a comprehensive review and in-depth analysis of the execution of the entire project. It not only covers the quality of the engineering entity and the efficiency of the construction progress, but also extends to multiple dimensions such as the level of safe production management and the effect of environmental protection. In the specific implementation, the key indicators such as the installation accuracy, stability and safety of the crane should be strictly inspected and evaluated to ensure that they meet the design specifications and use requirements; the construction progress should be compared and analyzed in stages and overall to find out the key factors affecting the progress plan, such as material supply, construction technology, weather environment, etc., and the ability of the project to be completed on time should be evaluated accordingly; the implementation effect of various safety measures during the construction process should be comprehensively evaluated to check whether safety accidents have occurred and their response and handling to improve the safety level of future projects; pay attention to the compliance with environmental protection policies and the implementation of the green building concept, analyze the impact of construction activities on the environment, and propose improvement measures to achieve the dual improvement of economic and environmental benefits. Through systematic sorting and scientific evaluation, a detailed and accurate project results summary report is formed to provide strong data support and reference basis for optimizing design plans, improving construction processes, and improving project management levels.

Lessons learned and suggestions for improvement

Based on the project summary, we deeply explore successful experiences and potential problems, and extract the essence and lessons of project management with universal significance. In view of the difficulties and challenges encountered in construction, we put forward targeted improvement suggestions, such as introducing more advanced construction technology, improving safety management system, and strengthening environmental protection construction concepts. At the same time, we should attach importance to summarizing and inheriting historical experience, transforming the successful practices and failed lessons of past projects into valuable assets for future projects, and continuously improving the scientificity and effectiveness of project management through continuous improvement and innovation, so as to promote the healthy development of the entire industry.