3 Ton Electric Chain Hoist

Introduction to 3 Ton Electric Chain Hoist

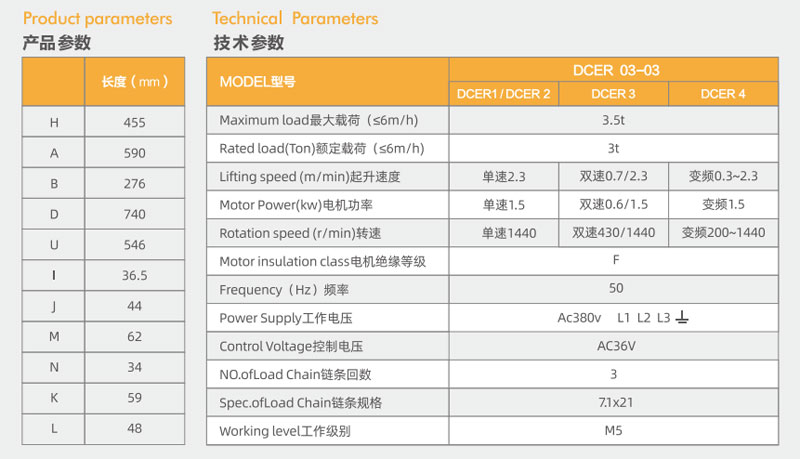

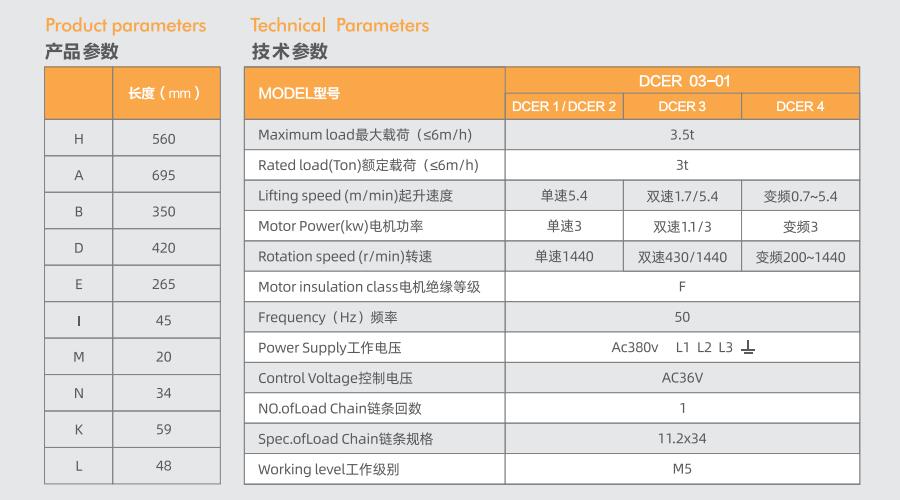

A 3 ton electric chain hoist is a powerful and efficient lifting device designed for material handling in various industries, including construction, manufacturing, warehousing, and logistics. Dongqi Crane offers high-quality electric chain hoists that ensure smooth, safe, and precise load lifting with minimal effort.

Our 3-ton electric chain hoists come in different configurations, including low headroom, fixed, and trolley-mounted models, making them suitable for diverse applications. Whether you need a compact hoist for tight spaces or a mobile solution for workshop operations, Dongqi Crane provides reliable lifting equipment tailored to your needs.

Types of 3 Ton Electric Chain Hoists

Dongqi Crane offers a range of 3-ton electric chain hoists designed for different lifting applications. Each type has unique features to suit specific workspace requirements. Below is a detailed breakdown of the three main configurations:

1. Low Headroom (Low Clearance) Electric Chain Hoist

Best for: Spaces with limited vertical clearance

Key Features:

- Compact Design: Minimizes the distance between the hook and the beam, maximizing usable lifting height.

- Lightweight Construction: Reduces structural load while maintaining high strength.

- Precise Load Control: Smooth variable-speed lifting for delicate operations.

Applications:

✔ Assembly lines with low ceilings

✔ Small workshops and maintenance areas

✔ Confined industrial environments

2. Fixed Mount Electric Chain Hoist

Best for: Stationary lifting in a single location

Key Features:

- Simple Installation: Direct mounting to beams or support structures.

- Cost-Effective: No additional trolley system required.

- Sturdy & Reliable: Ideal for repetitive lifting tasks in one spot.

Applications:

✔ Production line lifting stations

✔ Machinery maintenance and repair

✔ Fixed-position material handling

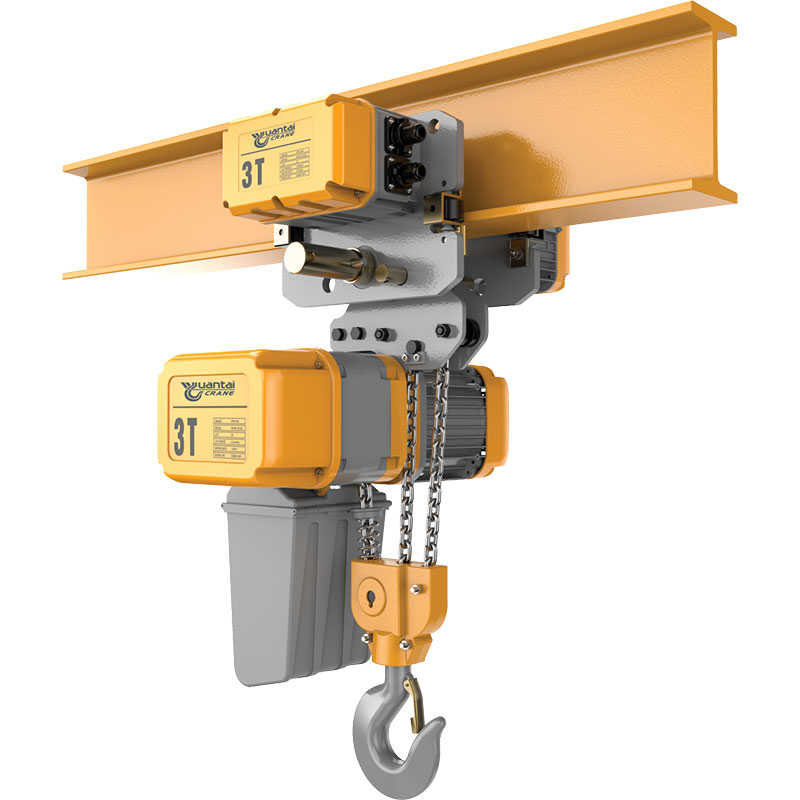

3. Trolley-Mounted Electric Chain Hoist (3 Ton Electric Chain Hoist with Trolley)

Best for: Moving loads horizontally along a beam

Key Features:

- Manual or Motorized Trolley Options:

- Manual trolley: Push/pull movement (economical choice).

- Motorized trolley: Powered travel for effortless horizontal transport.

- Increased Workspace Coverage: Moves loads across longer spans.

- Enhanced Flexibility: Ideal for dynamic work environments.

Applications:

✔ Warehouse loading/unloading

✔ Large-scale manufacturing operations

✔ Construction material handling

Choosing the Right 3 Ton Electric Chain Hoist

| Feature | Low Headroom | Fixed Mount | Trolley-Mounted |

|---|---|---|---|

| Space Efficiency | ✅ Best | ⚠ Moderate | ⚠ Depends on setup |

| Mobility | ❌ No | ❌ No | ✅ Yes (Manual/Motorized) |

| Cost | ⚠ Moderate | ✅ Lowest | ⚠ Higher (if motorized) |

| Best For | Tight spaces | Fixed lifting | Moving loads horizontally |

Which One Should You Choose?

- Need maximum lifting height in a small space? → Low Headroom Hoist

- Only require lifting in one spot? → Fixed Mount Hoist

- Need to move loads along a beam? → Trolley-Mounted Hoist

Key Features of Dongqi Crane’s 3 Ton Electric Chain Hoist

Dongqi Crane’s 3 ton electric chain hoists are engineered with premium components and innovative technologies to deliver superior performance, safety, and durability. Below we break down the exceptional features that set our hoists apart in the material handling industry.

1. Superior Lifting Performance

- Precision Control System: Variable frequency drive (VFD) option available for smooth acceleration/deceleration

- Dual-Speed Operation: Standard 8/2 m/min speeds (adjustable to customer requirements)

- High-Efficiency Motor: Class F insulation, IP54 protection grade, with thermal overload protection

- Reduced Voltage Starting: Prevents power surges and extends motor life

2. Enhanced Safety Mechanisms

- Dual Brake System: Primary electromagnetic brake + secondary mechanical load brake

- Overload Protection: Intelligent limiter automatically cuts power at 110% rated capacity

- Emergency Stop: Instant shutdown via accessible emergency button

- Phase Protection: Prevents damage from incorrect power supply connection

- Limit Switches: Upper/lower travel limits with automatic cut-off

3. Robust Construction & Durability

- Aircraft-Grade Load Chain: Grade 80 alloy steel, quenched and tempered

- Forged Steel Hook: 360° rotation with safety latch, tested to 125% capacity

- Heavy-Duty Gearbox: Hardened alloy steel gears with oil bath lubrication

- Corrosion Protection: Epoxy powder coating + zinc plating on critical components

4. Smart Operation Features

- Ergonomic Pendant Control: IP65 rated with clearly marked functions

- Optional Radio Remote: Up to 100m wireless control range

- Load Indicator: Digital display shows real-time weight (optional)

- Low Voltage Control: 24V/36V control circuit for operator safety

5. Maintenance & Service Advantages

- Modular Design: Quick replacement of components minimizes downtime

- Self-Diagnostic System: Fault codes displayed for easy troubleshooting

- Lubrication Points: Clearly marked for routine maintenance

- Sealed Bearings: Lifetime lubricated for reduced maintenance needs

6. Customization Options

- Power Supply: 220V/380V/415V, 50/60Hz, single or three phase

- Special Environments: Explosion-proof, high-temperature, or marine versions

- Lifting Height: Standard 3m-30m, customizable as needed

- Special Attachments: C-hooks, spreader beams, or vacuum lifters

Why These Features Matter

Each feature has been carefully engineered to address real-world challenges:

- The dual brake system ensures failsafe operation even during power failures

- Aircraft-grade chains provide 4x longer service life than standard chains

- VFD control prevents load swing for precise positioning

- Modular design reduces maintenance costs by up to 40%

Dongqi Crane’s 3 ton electric chain hoists combine these advanced features with rigorous quality control (each unit undergoes 25+ performance tests) to deliver unmatched reliability. Our hoists maintain 99.3% uptime in industrial applications, backed by a comprehensive 18-month warranty.

Upgrade your material handling with these premium features – contact Dongqi Crane today for a customized solution!

Applications of 3 Ton Electric Chain Hoist

- Manufacturing: Lifting heavy machinery and components.

- Construction: Moving building materials and equipment.

- Warehousing: Loading and unloading goods efficiently.

- Automotive: Handling engines, transmissions, and vehicle parts.

- Maintenance & Repair: Assisting in equipment servicing.

Why Choose Dongqi Crane?

- Competitive Pricing: Get the best 3 ton electric chain hoist price without compromising quality.

- Wide Availability: Our hoists are for sale globally, with reliable shipping and support.

- Custom Solutions: We offer tailored hoist configurations to meet specific requirements.

- Expert Support: Professional guidance for installation, operation, and maintenance.

Find Your Ideal 3 Ton Electric Chain Hoist Today!

Whether you need a 3 ton electric chain hoist with trolley, a single-phase model, or a cost-effective fixed hoist, Dongqi Crane has the perfect solution. Contact us today for more details and get a competitive quote on our high-performance lifting equipment!

Browse our selection of 3 ton electric chain hoists for sale and enhance your material handling efficiency!

Dongqi Crane – Your Trusted Partner in Lifting Solutions!