1 ton electric chain hoist

Introduction to 1 Ton Electric Chain Hoist

A 1 ton electric chain hoist is a versatile and efficient lifting device designed for material handling in various industries, including manufacturing, construction, warehousing, and logistics. Dongqi Crane offers high-quality electric chain hoists that ensure safety, durability, and precision in lifting operations.

Our 1 ton electric hoist is ideal for applications requiring smooth and controlled lifting of heavy loads. With options like low headroom, fixed, and trolley-mounted configurations, these hoists provide flexibility for different workspace requirements.

Types of 1 Ton Electric Chain Hoists

Dongqi Crane offers a range of 1 ton electric chain hoists designed for different lifting applications. Below is a detailed breakdown of the three main types:

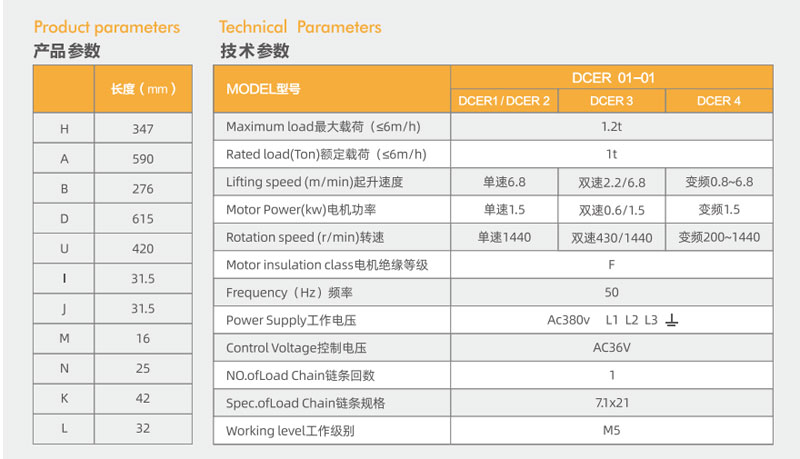

1. Low Headroom Electric Chain Hoist

Best for: Workspaces with limited vertical clearance.

Key Features:

- Compact Design: Minimizes the distance between the hook and the beam, maximizing usable lifting height.

- Lightweight Construction: Reduces strain on supporting structures.

- Precision Control: Smooth lifting and lowering with variable speed options.

- Applications:

- Assembly lines with low ceiling heights.

- Maintenance work in confined spaces.

- Small workshops and garages.

Advantages:

✔ Saves vertical space while maintaining full lifting capacity.

✔ Ideal for repetitive lifting in tight areas.

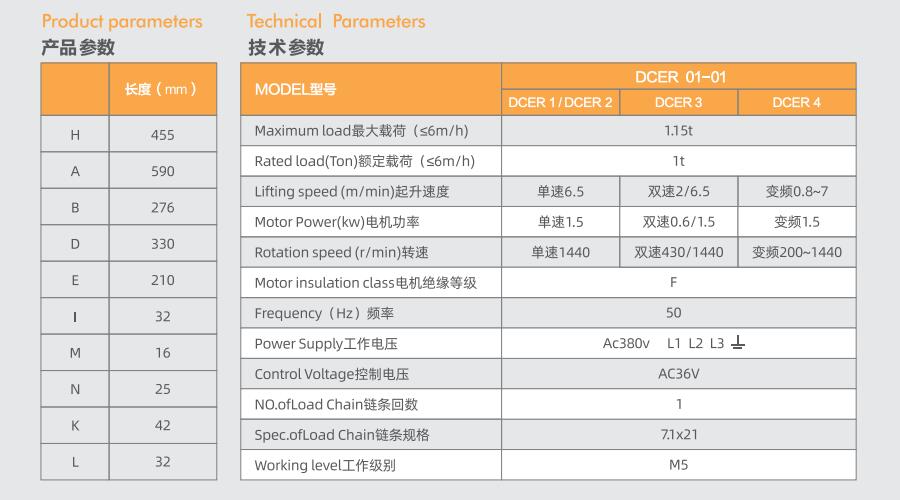

2. Fixed Electric Chain Hoist

Best for: Permanent lifting in a single location.

Key Features:

- Stationary Mounting: Securely attached to beams, brackets, or frames.

- Robust Build: Heavy-duty construction for long-term reliability.

- Simple Operation: Easy-to-use controls for consistent performance.

- Applications:

- Production lines with fixed lifting points.

- Machinery installation and maintenance.

- Loading/unloading in warehouses with designated workstations.

Advantages:

✔ No need for mobility—ideal for dedicated lifting spots.

✔ Lower maintenance compared to trolley-mounted hoists.

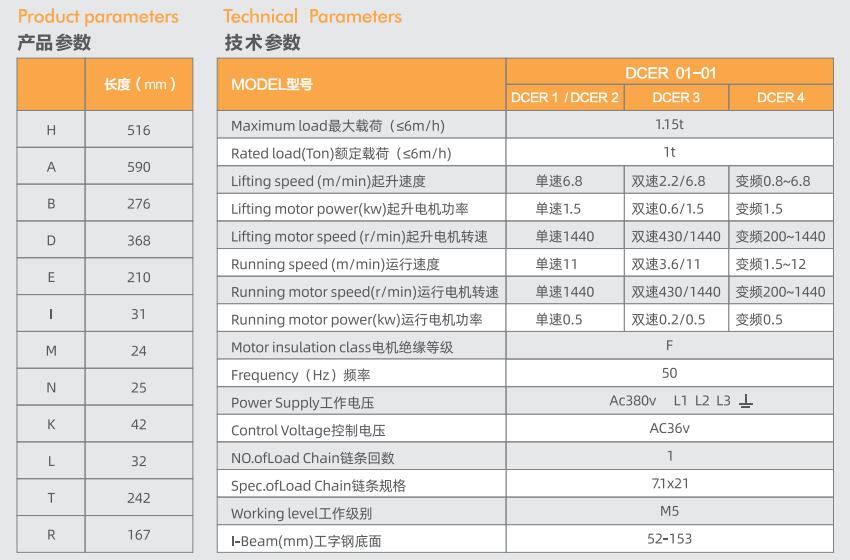

3. 1 Ton Electric Chain Hoist with Trolley (Running Type)

Best for: Applications requiring horizontal movement.

Key Features:

- Trolley System: Allows smooth travel along an I-beam or monorail.

- Manual or Motorized Trolley Options:

- Manual Push Trolley: Cost-effective, best for light-duty use.

- Motorized Trolley: Powered movement for heavy or frequent transport.

- Enhanced Flexibility: Covers a wider work area compared to fixed hoists.

- Applications:

- Warehouses for moving goods across aisles.

- Workshops requiring flexible load positioning.

- Construction sites for material distribution.

Advantages:

✔ Increases workspace efficiency by enabling lateral movement.

✔ Reduces manual labor when paired with a motorized trolley.

Choosing the Right 1 Ton Electric Chain Hoist

When selecting a hoist, consider:

- Workspace Constraints: Low headroom vs. open areas.

- Mobility Needs: Fixed position or movable operation.

- Power Supply: 110V, 220V, or 380V compatibility.

- Budget: Manual trolley vs. motorized trolley cost differences.

Dongqi Crane provides customized 1 ton electric chain hoists to match your specific requirements. Whether you need a low headroom, fixed, or trolley-mounted hoist, we have the right solution for you.

Key Features of Dongqi’s 1 Ton Electric Chain Hoist

Dongqi Crane’s 1 ton electric chain hoist stands out in the market due to its superior engineering, safety features, and operational efficiency. Below is a detailed breakdown of its key features:

1. Robust Load Capacity & Performance

- 1 Ton (1000 kg) Lifting Capacity – Reliably handles heavy loads with precision.

- Duty Cycle – Designed for medium to heavy-duty operations (typically Class 2 or 3).

- Smooth Start/Stop – Prevents load swinging for safer material handling.

2. High-Quality Lifting Chain

- Alloy Steel Chain – Heat-treated for high tensile strength and wear resistance.

- Self-Lubricating Design – Reduces maintenance needs and extends service life.

- Overload Protection – Automatic cut-off prevents damage from excessive loads.

3. Motor & Power Options

- Efficient Electric Motor – Provides consistent power with minimal energy consumption.

- Voltage Options – Available in:

- 110V (Standard for light industrial use)

- 220V / 380V (For higher power requirements)

- Thermal Protection – Prevents motor burnout due to overheating.

4. Safety Mechanisms

- Double Brake System – Ensures failsafe load holding (mechanical + electromagnetic braking).

- Emergency Stop Button – Immediate shutdown in critical situations.

- Phase Protection – Prevents damage from incorrect power supply connections.

- Limit Switches – Upper and lower travel limits for safe operation.

5. Control & Operation

- Variable Speed Control – Allows precise load positioning (standard or optional).

- Pendant Control – Ergonomic, waterproof, and easy-to-use.

- Remote Control Option – Wireless operation for improved convenience.

6. Durability & Maintenance

- IP54 / IP55 Protection – Resistant to dust and water splashes (suitable for harsh environments).

- Corrosion-Resistant Coating – Extends lifespan in humid or industrial conditions.

- Easy Maintenance – Modular design simplifies inspections and part replacements.

7. Customization Options

- Trolley Types – Manual push, geared, or motorized trolley for different mobility needs.

- Special Hook Designs – C-hook, swivel hook, or other attachments.

- Explosion-Proof Version – Available for hazardous environments (ATEX certification).

Why Dongqi’s 1 Ton Electric Chain Hoist?

✔ Reliable & Long-Lasting – Built with premium materials for industrial-grade durability.

✔ Safety-First Design – Multiple fail-safes to protect operators and loads.

✔ Energy Efficient – Low power consumption without compromising performance.

✔ Versatile Configurations – Adaptable to different workspaces and lifting needs.

Interested in a customized solution? Contact Dongqi Crane today for expert advice and competitive pricing!

This refined section provides a technical yet easy-to-understand breakdown of the hoist’s features, helping buyers make informed decisions. Let me know if you’d like any modifications!

Applications of 1 Ton Electric Chain Hoist – Industry-Specific Uses

Dongqi Crane’s 1 ton electric chain hoist is engineered for versatile material handling across multiple industries. Below is a comprehensive breakdown of its key applications:

1. Manufacturing & Assembly Operations

- Production Line Handling

- Precisely moves components between workstations

- Installs heavy machinery parts with controlled positioning

- Automotive Manufacturing

- Engine and transmission assembly

- Body panel positioning and installation

- Metal Fabrication

- Lifting steel plates, beams, and fabricated parts

- Positioning heavy molds in press machines

2. Warehousing & Logistics

- Loading Dock Operations

- Unloading heavy shipments from trucks

- Transferring palletized goods to storage racks

- Inventory Management

- Vertical movement of stock in high-bay warehouses

- Reorganizing storage layouts efficiently

- Order Fulfillment

- Handling bulky items for shipment preparation

- Positioning heavy crates for packaging

3. Construction & Infrastructure

- Job Site Material Handling

- Lifting construction materials to elevated work areas

- Positioning steel beams and concrete forms

- Equipment Installation

- HVAC system component placement

- Electrical transformer and generator setting

- Maintenance Work

- Replacing heavy mechanical components

- Facilitating structural repairs

4. Maintenance & Repair Facilities

- Industrial Equipment Servicing

- Removing and installing heavy motors/pumps

- Positioning large mechanical assemblies

- Vehicle Maintenance

- Engine removal/installation in repair shops

- Suspension system component handling

5. Specialized Industrial Applications

- Energy Sector

- Handling turbine components

- Maintenance of heavy electrical equipment

- Shipbuilding & Repair

- Positioning ship components

- Engine room equipment handling

- Mining Operations

- Underground equipment maintenance

- Processing plant component installation

Key Advantages Across All Applications:

- Precision Control: Micro-adjustment capability for delicate positioning

- Space Efficiency: Low headroom models ideal for confined spaces

- Operational Safety: Built-in overload and emergency stop protection

- Labor Savings: Reduces manual handling requirements significantly

Industry-Specific Configurations Available:

- Explosion-proof models for chemical/petroleum environments

- Corrosion-resistant units for marine applications

- High-cycle versions for continuous operation facilities

For tailored solutions matching your specific application requirements, contact Dongqi Crane’s engineering team for a customized consultation. Our experts will recommend the optimal 1 ton electric chain hoist configuration for your operational needs.

Enhance your material handling efficiency today – request a quote for your industry-specific solution!

Get Your 1 Ton Electric Chain Hoist Today!

Looking for a reliable 1 ton electric chain hoist 110V or a 1 ton electric chain hoist with trolley? Dongqi Crane provides top-tier lifting solutions tailored to your requirements.

Contact us now for the best 1 ton electric hoist price and expert advice!