Metallurgical Industry

The role of metallurgical industry in Pakistan

The metallurgical industry in Pakistan is of significant importance to the country’s economy. Metallurgical industry refers to the production of metal and metal-based products, including iron and steel, alloys, metal wires, pipes and tubes, and other metal components and products.

The Pakistan metallurgical industry has a long history and has been developing continuously. It is one of the important pillars of the national economy, especially in terms of exports. The metallurgical industry in Pakistan mainly produces iron and steel, and its products have been exported to more than 100 countries and regions. In recent years, the government of Pakistan has also introduced a series of policies to support the development of the metallurgical industry, including tax exemptions, preferential loans, and other preferential policies.

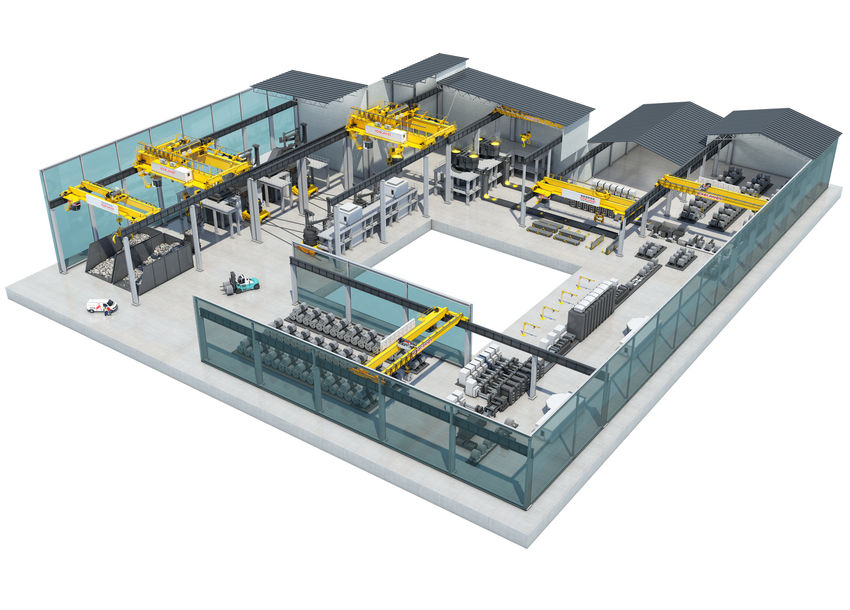

Crane Equipment for Metals Industry

We know the hazards and challenges of the metals production industry: open flame, molten metal, severe heat, dangerous loads and continuous production demands. Our advanced lifting equipment, technologies and service can improve the safety and productivity of operations across every area of your plant.

- Double-girder ladle handling cranes: A ladle handling crane lifts large, open-topped cylindrical containers (ladles) filled with liquid metal to the basic oxygen furnace (BOF) for mixing. The raw materials of iron ore and coking coal are combined to produce solid metallic iron, and this iron added to scrap metal creates steel. The crane also transports the liquid iron or steel from the BOF and electric arc furnace to the continuous casting machine.

- Four-girder charging cranes: A charging crane is critical in steel production. To make steel, a charging crane feeds an electric arc furnace (EOF) in the charging bay and should be able to deliver hot metal to the turret station of a continuous casting machine (CCM) or the ladle furnace (LF). This is a heavy-duty, continuous operation. The same crane can be a backup for the ladle crane if needed. Charging cranes are sometimes called teeming cranes.

- Slab and billet handling cranes: A slab and billet crane is a highly maneuverable electric overhead traveling (EOT) crane that transports large pieces of hot, soft metal – also known as slabs and billets – from the melt shop to its next destination. Because it is so hazardous, the melt shop is usually some distance away from other production locations. The crane feeds the slabs and billets into shaping rollers, takes the metal to be reheated in another furnace before shaping, moves the steel that has been shaped to another conveyor for further processing or delivers it to a storage area.

- Coil and plate handling cranes: A coil and plate handling crane handles metal bars, plates, and coils during machining processes. They can be designed for both indoor and outdoor use. Due to the wide variety of materials they need to handle, such a crane can be fitted with a variety of lifting devices that change with the nature of the material.

- Scrap handling cranes:A scrap handling crane handles scrap metal in the scrapyard of a steel mill. Scrap arrives by sea, rail, or road, stays in the scrapyard until it can be processed, and eventually gets melted down by the smelter in a melt shop. Difficult to handle, scrap has no defined shape for a hook or tong to fit onto, and it is often mixed, so it requires sorting. A scrapyard crane has to fit the size of the vehicles that deliver the scrap and must be able to access the right materials quickly from all parts of the storage area.

- Overhead Cranes: In the metallurgical industry, bridge cranes are mainly used for lifting and transporting large metal materials and equipment. For example, in the rolling workshops of steel companies, bridge cranes can be used to lift billets, steel and other materials to assist in completing production processes such as rolling and shearing. In addition, bridge cranes can also be used to transport large smelting equipment, mechanical parts, etc.

Expertise for Metallurgical Industry

The reason why cranes are used in the metallurgical industry is that during the metallurgical production process, a large number of heavy objects need to be transported, transferred, and hoisted. These tasks require the use of various types of mechanical equipment such as cranes to complete. Cranes are widely used in the metallurgical industry. For example, in steel enterprises, they are used to lift heavy objects such as hot-rolled steel coils and plates, and assist in completing production processes such as cold rolling, straightening, and packaging. In the non-ferrous metal industry, it is used to lift molten metal, semi-finished products and finished products in smelting furnaces. In the building materials industry, it is used to lift cement, bricks, slates and other building materials.

The role of cranes in the metallurgical industry is to improve work efficiency and reduce workers’ labor intensity. However, there are certain safety risks when using cranes, so operators must be trained to understand the operating procedures and safety regulations of the equipment. During operation, it is necessary to maintain a stable operating state and prevent sudden acceleration, sudden braking, etc. to avoid equipment damage and casualties. In addition, equipment must be inspected and maintained regularly to ensure its normal operation and service life.

Customer Reference Stories

We provide various types of customized overhead cranes, gantry cranes and other lifting equipment for steel rolling mills, steel mills, steel coil mills and scrap steel recycling plants in Pakistan. If you are interested in our project cases, you can contact us for details.

Provided the design, manufacture and installation of a 5-ton grab bridge crane for a mine in Pakistan

In 2016, we successfully completed the installation of a 5-ton grab crane in Pakistan. This crane was designed and built to handle a wide range of lifting tasks, making it a valuable addition to the lifting equipment fleet.

The 5-ton grab crane was custom-made to meet the specific needs of the customer, ensuring it is suitable for their lifting requirements. It features a robust structure and advanced lifting systems that provide precise control and handling of loads. The grab crane is equipped with a powerful grab that can grasp and lift various materials efficiently.

The installation process was carried out by our experienced team of engineers and technicians. They ensured that the crane was installed correctly and safely, following all the necessary safety standards and regulations. The installation was completed on time and within budget, delivering a reliable and efficient lifting solution to the customer.

Customized overhead crane solution for Pakistan steel rolling mill

We need to provide customers with a complete set of crane solutions. For this purpose, we have designed 6 QD type double beam overhead cranes with different parameters and 1 QZ type grab bucket overhead crane. This order will start production in January 2021 and complete production in June 2021, with a production cycle of 5 months. Our engineers have gained a lot of friendship from customers after assisting them in completing the installation.

Our team of experts has extensive knowledge and expertise in the design and manufacture of overhead cranes, including those used in steel rolling mills. We understand the unique challenges and safety requirements of this industry, and we apply this knowledge to deliver the most suitable solution for your specific needs.

Our customized overhead crane solutions for steel rolling mills are designed to handle the heavy loads and high lifting heights required in this industry. We offer a range of lifting capacities, spans, and configurations to ensure that your crane can handle the weight and size of your loads effectively. We also provide special lifting attachments and operator training to maximize efficiency and safety.