Automotive Industry

Pakistan’s automotive industry is an important part of the country’s economy and contributes significantly to economic growth and employment.

First of all, from an economic perspective, the automobile industry accounts for a certain proportion of Pakistan’s GDP. In 2012, the industry contributed 2.8% to GDP and had a turnover of over Rs 30,000 crore. In addition, the automotive industry is also an important manufacturing sub-sector in the country, employing approximately 3.5 million workers.

Secondly, from the perspective of output, Pakistan’s automobile production has increased in recent years. From 2012 to 2013, Pakistan’s automobile market production capacity reached 751,887 units. These vehicles mainly include cars, trucks, buses, motorcycles, tricycles and tractors, most of which are manufactured by Japanese companies such as Honda, Suzuki and Toyota.

Finally, from the perspective of industrial structure, Pakistan’s automobile industry has also driven the development of other related industries, such as steel, automobile parts and other upstream industries. Currently, there are approximately 1,700 auto parts manufacturers in Pakistan. These companies assemble and manufacture various auto parts and provide support for the entire automotive industry chain.

Crane Equipment for Automotive Industry

The role of cranes in the automotive industry needs to meet the following requirements:

Firstly, under the rated load, the workload of the lifting components or the larger weight of the mold must be considered, and a safety margin must be left.

Next is to increase the height. In the design, it is necessary to consider both the height of the lifting car components and the lifting height required for the lifting motion itself, as well as the safety distance, as well as the working level, travel length, and wheel pressure. Considering the load and working degree, if the mold does not fluctuate up and down frequently in automobile manufacturing, A5 level can be selected. The length of the edge area should also be noted, and this data should be used to determine the working length of the crane.

- The application of gantry cranes in the automotive industry: The application of gantry cranes in automotive manufacturing mainly involves lifting car parts and replacing molds in various workshops. Due to the limited space of automotive manufacturers, the weight of gantry cranes should be reduced to reduce basic construction costs, and design and application should be based on different workshop conditions.

- The application of overhead cranes in automobile manufacturing: On automobile assembly lines, overhead cranes can be used to move and lift automobile components, such as engines, transmissions, axles, etc., to assist in the assembly process of automobiles. In addition, overhead cranes can also be used for handling and stacking car parts, as well as lifting equipment during car maintenance and repair processes.

- The application of workstation cranes in automobile manufacturing: Workstation cranes usually use electric hoists as lifting mechanisms, which have the characteristics of simple structure, convenient operation, and flexible movement. In automobile manufacturing, workstation cranes can be customized according to different production needs, such as adding different fixtures and fixtures to meet different production requirements.

Application of jib cranes in the automotive industry

As like all other cranes and similar machinery, the primary objective of a jib crane is to move stuff from one place to another. Jib Crane, aided with 360-degree motion which facilitates the circular movements of loads of bulky objects easier and relatively quickly. They are usually capable of turning, pivoting, transporting and lifting loads with high precision throughout the entirety of the assembly process in the automobile industry. Especially when handling press tools for the body parts of the vehicle and moulding tools in producing plastic parts, the jib crane becomes very useful.

The entirety of the automobile industry relied heavily on cranes for their smooth functioning and maintaining the high-speed production line. Any issues with the crane operability will affect the entire production line drastically. Jib crane is best suited for such requirements as they are quite low on maintenance and very robust. The industry depends on them heavily for getting the job done quickly and reliably. Shorter production time can be achieved with the use of jib cranes. Jib crane requires very little time of installation and can be relocated with relative ease.

The cost of installation and production downtime caused by relocation can be primarily reduced using Jib cranes in the automobile industry. A simple forklift is sufficient to move a jib crane from one place to another. Human effort is vastly reduced with the use of jib cranes. The operational ease they offer makes it convenient for almost anyone within the industry to operate them effectively, even without extensive training. As jib cranes save time, workforce and money, they are vastly revered by the automobile industry for quickening production procedures.

Expertise for Automotive Industry

When it comes to choosing the right level of automation, it’s important to understand the nature of what you are machining as well as your specific requirements and capabilities. Semi-automated lifting helps automotive manufacturers establish and sustain quality and customer satisfaction. From press and assembly lines to workstations and warehouses, our technology helps improve operation safety and productivity.

Semi-automation involves an operator picking the load and then pressing a button to instruct the crane to deliver it to a pre-determined destination. Our cranes already include many features to help maximize safety and productivity. Movements and cycles are automatically controlled, minimizing human error.

Dongqi crane Smart Features deliver specific benefits that enhance safety and productivity. Working alongside automotive manufacturers, Dongqi crane has developed Hook Centering, Snag Prevention and Active sway Control features to improve safety, speed and positioning. Smart Features reduce the risk of accidents, equipment collisions and load damage, and help protect people, products and infrastructure.

There are no solutions or products made specially for the automotive sector

Although the automotive industry has long been considered a major user of lifting equipment, there are almost no professional, customized lifting solutions in the automotive and truck manufacturing fields. Ready made designs may seem sufficient – but they must be the highest among high-end ready-made products.

For Dongqi Crane, given the modular design principle of our lifting equipment, we can use chain electric hoists or wire rope hoists to meet the application needs of most automotive customers. In the field of small components in the automotive industry, cranes themselves are quite standard for manipulating engine blocks, cylinder heads, etc.

“People’s interest lies more in what is underneath the hook. This is where specialization occurs. The intelligent technology of large stamping workshop cranes lies in anti roll control and other technologies, which is far from unique to the automotive industry.”

Nevertheless, the industry does have its unique needs. They are imposed due to the absolute need to deliver and deliver on time. Delay is unacceptable, and every second saved in production is crucial. The most important thing in the automotive industry is responsibility, which is the frequency of use. We have recently installed a hoist for a factory that produces car seats, which operates at a speed of 15 cycles per hour, in large quantities.

The second factor is speed, and the third factor is improving the controllability of the device. The two are interrelated: most hoists have two speeds, namely fast and slow. Fast refers to completing the hook and loading from the pickup point to the destination in the shortest possible time. When it reaches there, it needs to be slow for precise positioning.

Customer Reference Story

Car manufacturing plant uses container gantry crane to transfer goods

Improving Car Manufacturing Efficiency: The 100-Ton Rubber Tire Gantry Crane

In 2018, we supplied a rubber tire gantry crane with a lifting capacity of 100 tons to a car manufacturing plant in Singapore.

The high-capacity crane has been instrumental in streamlining the movement and assembly of heavy car components. The rubber tire gantry crane, with its impressive 100-ton lifting ability, offers a mobile and flexible lifting solution, which is vital for the fast-paced environment of a car manufacturing facility.

Given the vast weight it can support, the rubber tire gantry crane not only enhances production flow but also improves safety. Its maneuverability allows for precise placement of car parts without constraining the plant’s layout, thus maintaining a lean manufacturing process. This asset ensures that vital components are transported swiftly from one stage of the assembly to the next, minimizing delays and optimizing the production line’s efficiency.

The decision to employ such a powerful and adaptable piece of machinery demonstrates the plant’s commitment to innovation and continuous improvement. The crane’s rubber tires facilitate not only heavy lifting but also easy transition across various areas within the manufacturing compound, further proving its worth as a valuable addition to the automotive industry’s tools.

Current status of Chinese automobile industry in Pakistan

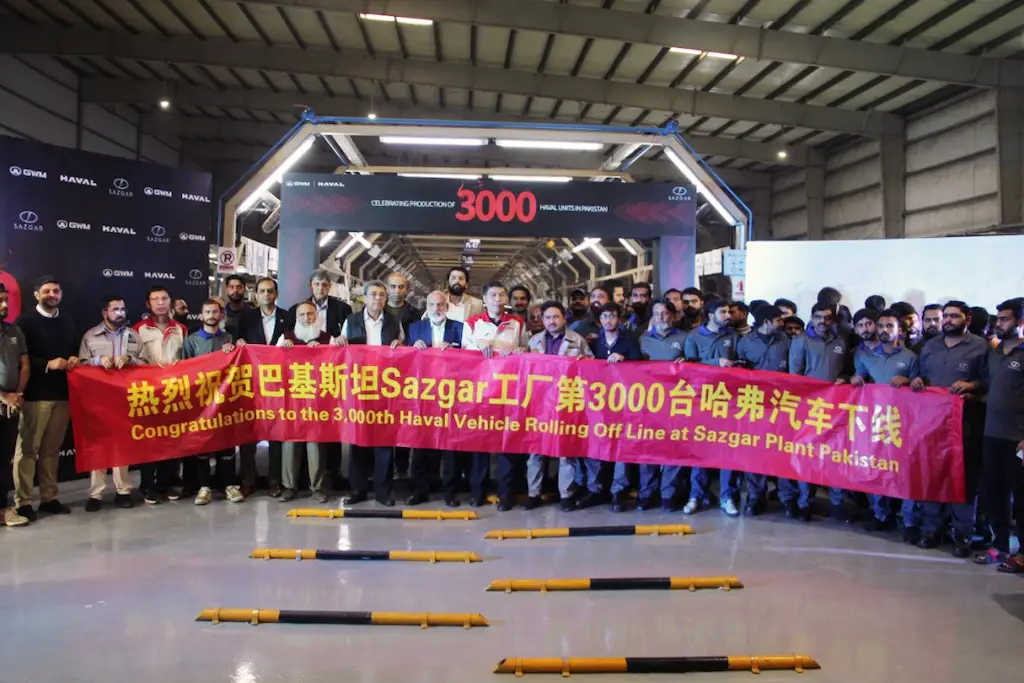

Recently, Great Wall Motors’ KD plant in Pakistan welcomed the 3,000th Haval H6 HEV off the assembly line one year after it was put into production. This milestone means that Great Wall Motors has ranked first in the local new energy market in just one year, once again It demonstrates GWM’s profound strength in adhering to the localization development strategy.

Great Wall Motors’ KD plant in Pakistan will be put into operation in November 2022, with a planned production capacity of 20,000 vehicles per year. At present, the first phase of the project has achieved the assembly of two SUVs, Haval H6/H6 HEV and Haval JOLION. As the first locally assembled new energy vehicle in Pakistan, Haval H6 HEV has opened a chapter in the new energy market. Relying on its advantages of greenness, intelligence, technology, and safety, it has become a benchmark product in the local automobile market, boosting the penetration of new energy in passenger cars in Pakistan. The rate increased to 2.3% from 0 last year.

Pakistan is one of the important markets for Chinese automobile companies to “go global”. In recent years, the investment and business development of Chinese automobile companies in Pakistan have been rapid, bringing significant changes and development to Pakistan’s automobile industry.

First of all, Chinese automobile companies have established multiple production bases and assembly plants in Pakistan, which has promoted the improvement of local automobile production capacity. Through cooperation with local Pakistani companies, these companies have introduced advanced production lines and technologies, allowing Pakistan’s automotive industry to develop rapidly.

Secondly, Chinese automobile companies have also provided a variety of automobile products to the Pakistani market, including passenger cars, commercial vehicles, trucks and other types of models. These models not only meet the needs of Pakistan’s domestic market, but are also exported to other countries and regions, bringing growth to Pakistan’s automobile exports.

In addition, Chinese automobile companies have also established a relatively complete sales network and after-sales service system in Pakistan, providing local consumers with a better car buying and using experience. These measures not only enhance the visibility and reputation of Chinese automobile brands in the Pakistani market, but also inject new vitality and impetus into Pakistan’s automobile industry.