Parameters of MH type 10t single beam gantry crane

The MH type 10t single beam gantry crane (hereinafter referred to as the 10 ton single main beam gantry crane) is a small and medium-sized crane with rail operation, which is used in conjunction with the 10 ton electric hoist gantry crane. It is suitable for a lifting capacity of 1-32 tons, a suitable span of 12-35 meters, and a working environment of -20 ℃ to+40 ℃.

Technical parameters of a 10 ton single beam gantry crane:

- Electric hoist gantry crane lifting capacity: 3T, 5T, 10T, 16T, 20 tons (non-standard customization is possible);

- Lifting height: 6M, 8M, 9M, 12M, 18M, 30 meters (customizable);

- Spans of 6.5M, 7.5M, 8.5M, 9.5M, 13.5M, 19.5M, 20.5M, 21.5M, 22.5M, 23.5M, and 25.5M (customizable);

- Running speed of large and small cars: 20M/MIN, 30M/MIN (can be customized according to non-standard design);

- Work level: A3/M3;

- Power supply: three-phase AC 380V 50HZ;

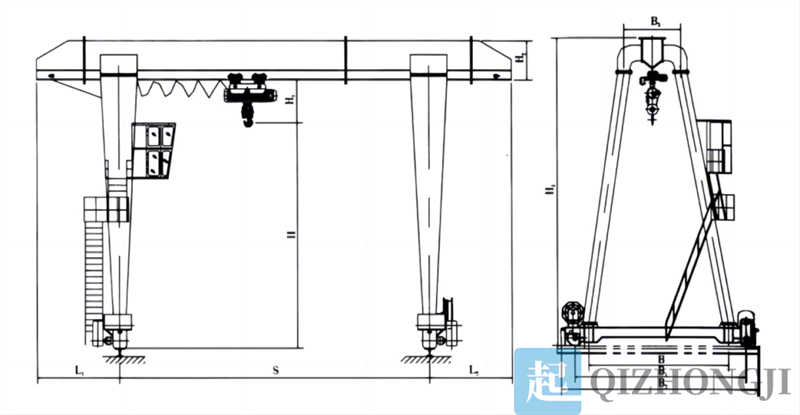

Structural diagram of a 10 ton single beam gantry crane

Outline dimension table for 10 ton single beam gantry crane

| Lifing Weight | t | 10 | |||||||

| Span | m | 12 | 16 | 20 | 24 | 30 | |||

| Lifting Height | m | 6/9 | |||||||

| Operating organization | Travelling Speed | Ground | m/min | 20 | |||||

| Controlling Room | 20/30 | ||||||||

| Motor | Ground | Model/kw | YSE90L-4/1.5×2 | ||||||

| Controlling Room | ZDR112L1-4/2.1×2 | Y2R132M2-6/4×2 | |||||||

| Hoist | Type No. | CD, MD | |||||||

| Liting Speed | m/min | 7 0.7/7 | |||||||

| Travelling Spood | m/min | 20 | |||||||

| Motor | Lifting | Model/kw | ZD,51-4/13 ZDS,15/4.5 | ||||||

| Travelling | ZDY21-4/0.8×2 | ||||||||

| Working class | A3 | ||||||||

| Steel Track Recommended | P38 | P43 | |||||||

| Power supply | 三相交流380V 50HZ | ||||||||

| The Crane Weight | Ground | t | 12.23/14.23 | 15.05/17.05 | 17,42/19,42 | 21.12/23.12 | 32.7 | ||

| Controlling Foom | t | 12.75/14.68 | 15.50/17.50 | 17.87/20.87 | 21.57/23.57 | 33.2 | |||

| Max.Wheel Pressure | KN | 97/102 | 105/110 | 113/118 | 121/126 | 149 | |||

| Basic Dimensions | L₁ | mm | 3000 | 4000 | 5000 | 8000 | 7500 | ||

| L₂ | mm | ||||||||

| H, | mm | 1350 | |||||||

| H₂ | mm | 1000 | 1100 | 1200 | 1300 | 1600 | |||

| H₃ | mm | 8350/1135 | 8450/1450 | 8550/11550 | 8650/11650 | 12250 | |||

| B | mm | 4500/5500 | 5500/6500 | ||||||

| B₁ | mm | 5500/6500 | 6500/7500 | ||||||

| B | mm | 6000/7100 | 7100/8100 | ||||||

| B₂ | mm | 1600 | |||||||