Construction industry

In the construction process, it is often necessary to move heavy objects. If these tasks are completed by manpower, not only is efficiency low, but it also poses great risks to the safety of workers. The use of cranes can effectively reduce the labor intensity of workers, reduce the occurrence of work-related accidents, and ensure the safety of workers.

The development level of Pakistan’s construction industry can be described as growing but with challenges. Pakistan’s construction sector has experienced significant growth in recent years, driven by various factors such as infrastructure development, urbanization, and government investment in key projects.

The government has prioritized infrastructure development, especially in the areas of roads, highways, railways, ports, and power generation. This has created opportunities for the construction industry to grow and develop. Additionally, Pakistan’s urban population is increasing rapidly, which has led to a demand for new housing, commercial spaces, and infrastructure to support the growing urban centers.

Crane Equipment for Construction industry

Overhead cranes: Overhead crane is a lifting equipment mainly used for indoor or outdoor transportation, loading and unloading of objects. In engineering construction, Overhead cranes are usually used in the following scenarios:

- Construction sites: Overhead cranes can be used for the transportation and loading and unloading of goods on indoor or outdoor construction sites. It can efficiently and quickly transport various heavy building materials, equipment, machinery and other items to designated locations, and can perform high-altitude operations as needed.

- Highway and bridge construction: It can be used for cargo transportation and equipment installation in highway and bridge construction. For example, a bridge crane can be used to pour concrete to high places or transport goods to the desired location.

- Port construction: Overhead cranes can not only be used for onshore construction, but also as loading and unloading equipment for containers, bulk cargo, and other goods in ports. By using bridge cranes, the loading, unloading, and movement of containers and other goods can be quickly and efficiently completed, improving the operational efficiency of the port.

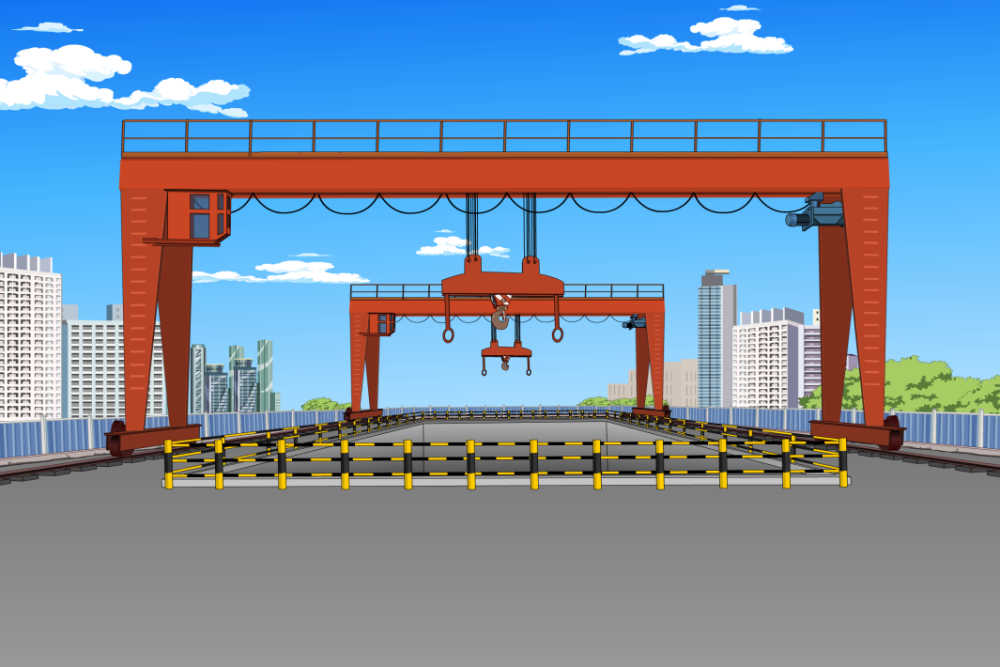

Gantry cranes: In construction, gantry cranes are mainly used for lifting operations in areas such as material yards, steel processing yards, prefabrication yards, and subway station construction work wellheads.

Rubber tire gantry (RTG) crane: RTG cranes are widely used in the construction field, such as lifting and transporting various building materials such as steel, glass, concrete structures, etc. on construction sites. RTG cranes have the advantages of flexibility, convenience, and high stability, making them easy to move and operate on construction sites.

Service for Construction Industry

Dongqi Crane provides comprehensive lifting equipment services for the construction industry, including the design, manufacturing, installation, commissioning, and maintenance of cranes.

In the construction industry, cranes are one of the essential equipment used for lifting and transporting various building materials, equipment, and personnel. As a professional lifting equipment service provider, Dongqi Crane has rich experience and a professional technical team, which can provide customers with high-quality lifting equipment services.

Specifically, the services provided by Dongqi Crane include:

- Crane design: Based on the needs and conditions of the construction project, provide customers with crane design services, including the type, specifications, performance, etc. of the crane.

- Crane manufacturing: manufacture crane equipment that meets customer requirements and design drawings.

- Crane installation: Dispatch professional technicians to the site to install cranes for customers, ensuring the stability and safety of the cranes.

- Crane debugging: Debugging the installed crane to ensure its performance and safety meet the requirements.

- Crane maintenance: Provide customers with crane maintenance consulting services and spare parts for faulty components.

In summary, Dongqi Crane provides comprehensive lifting equipment services for the construction industry, helping customers solve various lifting equipment problems and improving the efficiency and quality of construction projects.

Customer Reference Stories

Supplies cranes to Australian infrastructure project

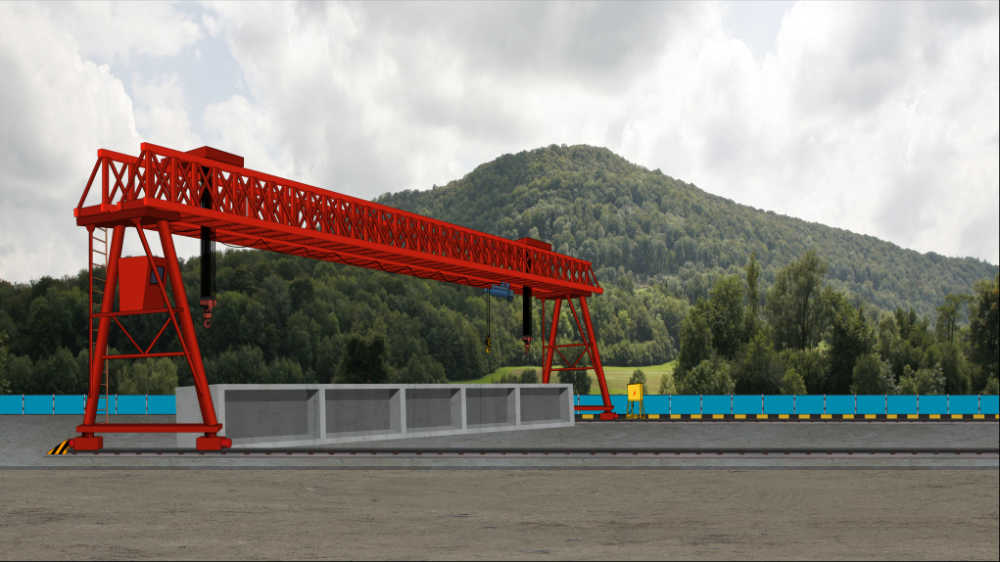

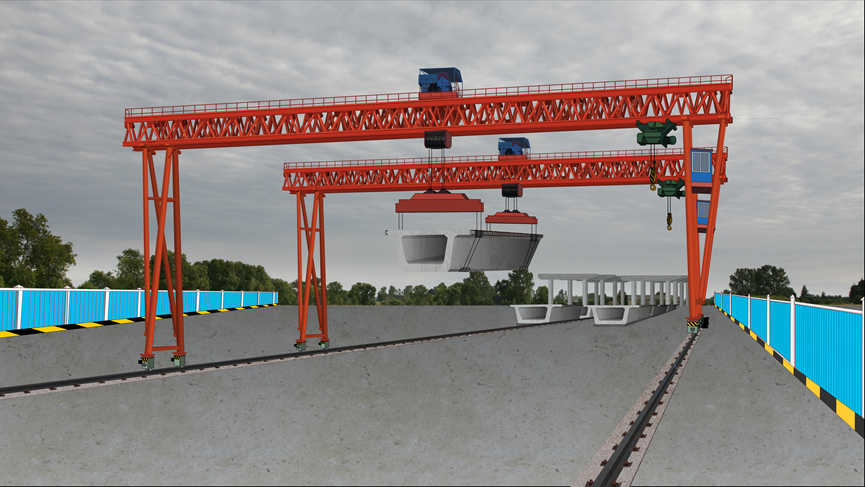

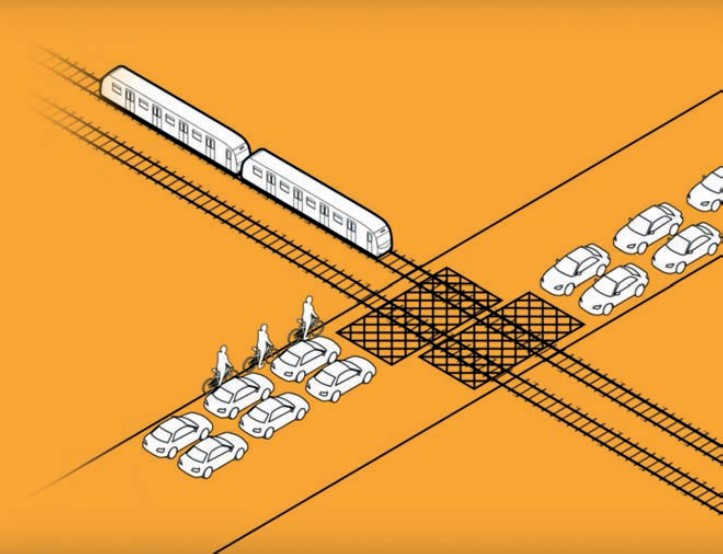

Custom-built gantry cranes are being used to handle and transport concrete precast elements for the first elevated rail line in Perth, Australia, as part of the Victoria Park-Canning Level Crossing Removal Project.

These mobile straddle transporters have been designed to fit the exact specifications of the Armadale Line. Each crane can lift 120t, with two required to operate at once for the project’s maximum lift of 140t.

Six gantry cranes will be used on the project and two are currently lifting and storing L-beams at the laydown storage site in Hazelmere. A total of 530 L-beams will be installed to build the overhead rail line. Each beam is made up of approximately eight truckloads of concrete and 13t of steel. The beams are 2.2m high, 30m long and weigh 130t.

By using gantry cranes, the footprint of works is said to be “significantly reduced as this type of crane will operate within the rail corridor, which allows more trees and vegetation to be retained”.

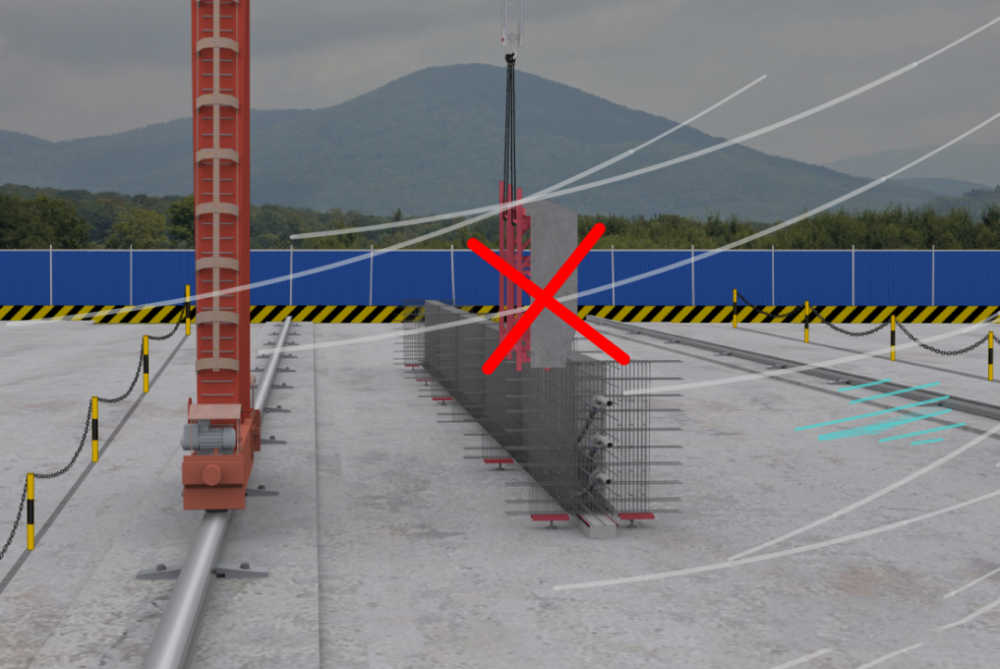

30-ton rubber tire gantry crane for a tunnel project in Singapore

RTG cranes are mainly used for container loading, unloading and stacking operations in ports, terminals, railways and other places. This kind of crane can be supported on pneumatic rubber tires and walk freely in the freight yard, and is used to transfer containers between the yard and the chassis truck. RTG cranes have the characteristics of flexible turning lanes and large working range, but because they are too large and heavy, they also put forward higher requirements for the drivers who control them.

The use of a 30-ton Rubber-Tyred Gantry (RTG) crane in a tunnel project for material handling demonstrates the versatility and efficiency of such cranes in various construction scenarios.