Top Running Crane Guide: Structure, Working Principle & Key Benefits

Introduction

A top running crane (also called a top-running overhead crane) is a heavy-duty lifting system designed for industrial applications requiring high load capacities and long spans. Unlike underhung cranes, which hang from ceiling structures, top running cranes move on rails mounted on top of elevated runway beams, making them ideal for heavy manufacturing, steel mills, and large-scale assembly operations.

In this guide, we’ll explore:

✔ Top running vs. under running cranes – Key differences

✔ Core components – Bridge, hoist, trolley, and runway system

✔ How it works – Movement and control mechanisms

✔ Advantages & applications – Why industries choose top running cranes

1. Top Running vs. Under Running Cranes: What’s the Difference?

Top running and under running (underhung) cranes serve different industrial needs. Here’s a quick comparison:

| Feature | Top Running Crane | Under Running Crane |

|---|---|---|

| Load Capacity | Up to 500+ tons | Typically <15 tons |

| Installation | Rails on runway beams | Suspended from ceiling |

| Clearance | Requires headroom | Space-saving, low clearance |

| Best For | Heavy industry (steel, construction) | Light-duty (warehouses, small shops) |

When to Choose a Top Running Crane?

✔ Need heavy lifting (50+ tons)

✔ Require long spans (20+ meters)

✔ Operating in high-temperature environments (e.g., foundries)

2. Core Components of a Top Running Crane

(Keywords: “top running crane parts”, “overhead crane components”, “bridge crane structure”)

A top running crane’s superior performance comes from its robust engineering. Let’s examine each critical component in detail:

A. Bridge Girder (Main Load-Bearing Structure)

(Keywords: “single vs double girder crane”, “crane bridge beam design”)

Function:

- Serves as the primary horizontal beam that spans the work area

- Supports all lifting forces and distributes weight to end trucks

Types:

- Single Girder Design

- Single beam construction (typically I-beam or box girder)

- Capacity: Up to 20 tons

- Advantages:

- Lower cost

- Requires less headroom

- Ideal for light to medium duty applications

- Double Girder Design

- Parallel beams with reinforced construction

- Capacity: 20-500+ tons

- Advantages:

- Higher load capacity

- Allows for auxiliary hoists

- Better hook height clearance

Material Specifications:

- ASTM A36 steel for standard applications

- ASTM A572 Grade 50 for heavy-duty use

- Corrosion-resistant coatings for harsh environments

B. End Trucks (Drive System & Support Structure)

(Keywords: “crane end carriage”, “overhead crane drive mechanism”)

Key Elements:

- Wheel Assemblies

- Forged steel wheels with hardened treads

- Typical configurations:

- 4-wheel (light duty)

- 8-wheel (heavy duty, better load distribution)

- Drive Motors

- AC or DC powered (10-200 HP depending on capacity)

- Common types:

- Gear-motor direct drive

- Shaft-mounted with reducer

- Braking Systems

- Fail-safe mechanical brakes

- Eddy current brakes for precision control

- Regenerative braking for energy efficiency

Technical Considerations:

- Wheel load calculations based on CMAA Class (A-F)

- Anti-derailment features for safety compliance

C. Hoist & Trolley Assembly (Lifting Mechanism)

(Keywords: “top running crane hoist types”, “overhead trolley system”)

Hoist Options:

| Type | Capacity Range | Speed | Best For |

|---|---|---|---|

| Electric Chain Hoist | 0.5-10 tons | 8-20 fpm | Light repetitive lifts |

| Wire Rope Hoist | 5-500+ tons | 2-60 fpm | Heavy industrial use |

| Explosion-Proof Hoist | 1-50 tons | 4-30 fpm | Hazardous environments |

Trolley Components:

- Cross travel drive system (gear motor + reducer)

- Guide rollers for smooth movement

- Bumper stops at travel limits

Advanced Features:

- Variable frequency drives (VFD) for precise speed control

- Load monitoring systems with digital readouts

D. Runway System (Structural Support)

(Keywords: “crane runway design”, “overhead crane rail installation”)

Structural Requirements:

- Runway Beams

- Typically wide-flange (WF) steel beams

- Size calculation based on:

- Crane capacity

- Span length

- Deflection limits (usually L/600)

- Rail Types

- A36 flat bar rails (light duty)

- ASCE rails (25-40 lb/yd for medium duty)

- Crane rail (1045 steel, 80-175 lb/yd for heavy duty)

- Support Columns

- Steel columns with reinforced base plates

- Foundation requirements:

- Minimum 3,000 psi concrete

- Anchor bolts sized per load calculations

Installation Critical Factors:

- Rail alignment tolerance: ±1/8″ over 20 feet

- Proper electrification (conductor bars or festoon systems)

- Vibration damping for high-speed applications

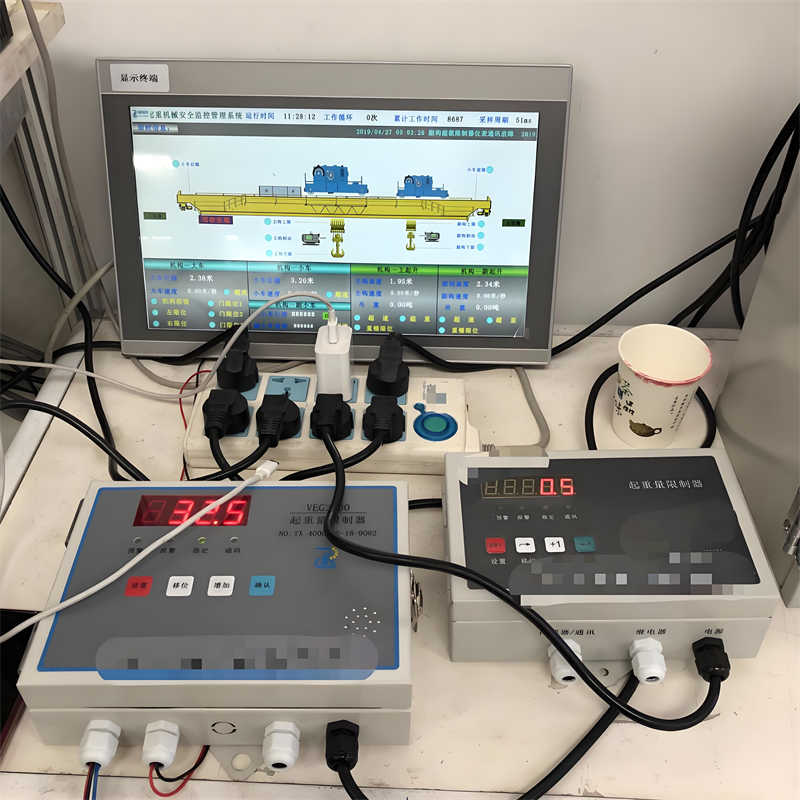

E. Control Systems (Operation Interface)

(Keywords: “overhead crane controls”, “crane pendant station”)

Common Configurations:

- Pendant Control

- Hardwired hanging station

- Buttons for:

- Bridge travel

- Trolley motion

- Hoist operation

- Radio Remote Control

- Wireless operation (900MHz or 2.4GHz)

- Range: Up to 500 feet

- Safety features:

- Emergency stop

- Signal loss protection

- Automated Systems

- PLC-controlled movement

- Pre-programmed lift sequences

- Anti-sway technology

Safety Components:

- Overload limit switches

- Emergency stop circuits

- Collision avoidance systems

F. Additional Optional Components

(Keywords: “crane accessories”, “overhead crane upgrades”)

- Load Indicators

- Digital readouts

- Overload alarms

- Lighting Systems

- LED work area lights

- Warning beacons

- Specialty Features

- Magnet systems for steel handling

- Vacuum lifters for delicate materials

- Rotating hooks for precise positioning

Why Component Quality Matters

Investing in high-quality components ensures:

✔ Longer service life (20+ years with proper maintenance)

✔ Reduced downtime (fewer breakdowns)

✔ Improved safety (meets OSHA/ANSI standards)

For optimal performance, always:

- Follow manufacturer’s lubrication schedules

- Conduct quarterly inspections

- Replace worn components before failure

Would you like me to elaborate on any specific subsystem or provide technical drawings?

3. How Does a Top Running Crane Work?

(Keywords: “top running crane operation,” “overhead crane working principle,” “how bridge cranes work”)

Top running cranes are engineered for precision lifting and movement in industrial environments. This section breaks down their mechanical operation, power systems, and control methods in detail.

1. Three-Axis Movement System

(Keywords: “crane XYZ movement,” “overhead crane kinematics”)

A top running crane operates along three primary axes for full-range material handling:

A. Bridge Travel (X-Axis – Longitudinal Movement)

- The entire crane moves along the runway rails.

- Powered by drive motors in the end trucks.

- Speed: Typically 20-100 ft/min (adjustable for precision work).

B. Trolley Traverse (Y-Axis – Cross-Movement)

- The trolley moves side-to-side along the bridge girder.

- Uses geared motor drives or friction wheels.

- Precision Feature: Some models have encoder feedback for millimeter-accurate positioning.

C. Hoist Lift/Lower (Z-Axis – Vertical Movement)

- The hoist raises or lowers loads via wire rope or chain.

- Lifting Speed: 2-30 ft/min (slower for heavy loads).

- Safety Systems:

- Upper/lower limit switches

- Overload protection

(Pro Tip: For hazardous areas, cranes can include explosion-proof components.)

2. Power Delivery Systems

(Keywords: “crane power supply options,” “festoon vs conductor bars”)

| System | Best For | Advantages |

|---|---|---|

| Conductor Bars | Heavy-duty, high-cycling | Minimal maintenance, high current capacity |

| Festoon Cable | Medium-duty applications | Cost-effective, flexible installation |

| Battery Pack | Wireless remote cranes | No trailing cables, portable |

Key Consideration:

- Conductor bars are preferred for foundries (heat-resistant).

- Festoon systems work well in warehouses with moderate usage.

3. Control & Automation Technologies

(Keywords: “overhead crane controls,” “automated bridge crane systems”)

A. Manual Control Methods

- Pendant Control

- Wired handheld unit with buttons for all movements.

- Safety Feature: Emergency stop button required by OSHA.

- Cabin Control

- Operator sits in an enclosed cab mounted on the crane.

- Used for frequent, high-precision operations.

B. Advanced Control Systems

- Radio Remote Control

- Wireless operation up to 100m distance.

- Allows ground-level visibility for safer lifts.

- Automated Operation (Industry 4.0)

- Programmable Logic Controllers (PLCs) for repeatable movements.

- Laser Guidance for millimeter-accurate positioning.

- IoT Sensors for predictive maintenance.

(Case Study: A German auto plant reduced lift times by 40% using automated top running cranes with RFID load tracking.)

4. Load Dynamics & Stability

(Keywords: “crane load sway control,” “bridge crane safety features”)

Critical Stability Factors:

- Load Distribution

- Center of gravity must stay within crane’s rated capacity.

- Anti-Sway Technology

- Advanced systems use accelerometers to dampen swing.

- Wind Considerations

- Outdoor cranes require wind speed indicators (per ANSI B30.2).

Safety Systems Checklist:

✔ Load moment indicators

✔ Emergency braking

✔ Collision avoidance sensors

5. Real-World Operation Sequence

(Keywords: “how to operate a top running crane,” “crane lifting procedure”)

Example: Moving a 50-ton Turbine

- Pre-Lift Inspection

- Verify rail alignment, hoist brakes, and load weight.

- Positioning

- Move bridge to turbine location (X-axis).

- Traverse trolley into position (Y-axis).

- Lifting

- Attach slings, lift slowly to test brake hold (Z-axis).

- Transport

- Move at reduced speed to minimize sway.

- Lowering

- Use “inch mode” for precise final placement.

(Training Note: OSHA requires certification for all overhead crane operators.)

Why This Matters for Buyers

- Understanding operation helps select the right control system.

- Proper use extends equipment life and prevents accidents.

- Automation can reduce labor costs by 30-50%.

4. Key Advantages of Top Running Cranes

✅ Higher Load Capacity – Handles 100+ tons (vs. underhung cranes’ 15-ton limit).

✅ Greater Span & Height – Ideal for large facilities (e.g., shipyards, power plants).

✅ Durability – Built for heavy-duty, high-cycle operations.

✅ Customizable – Adjustable speeds, automation options (e.g., smart crane systems).

5. Common Applications of Top Running Cranes

- Steel Mills – Handling molten metal, coils, and heavy billets.

- Power Plants – Lifting turbines, generators, and transformers.

- Shipbuilding – Moving large ship components.

- Aerospace – Assembling aircraft structures.

Conclusion: Is a Top Running Crane the Right Choice for Your Operation?

*(Keywords: *“top running crane selection guide”, “overhead crane buying factors”, “industrial crane ROI analysis”)

1. Decision Checklist: When to Choose a Top Running Crane

*(Keywords: *“top running crane vs alternatives”, “crane selection criteria”)

Choose a Top Running Crane If You Need:

✔ Heavy Load Capacity (20+ tons, up to 500+ tons)

✔ Long Spans (50-150 ft between runways)

✔ High Duty Cycles (Continuous operation in shifts)

✔ Precision Handling (Anti-sway systems, micro-speed control)

Consider Alternatives When:

- Loads < 5 tons → Underhung crane

- Limited headroom → Low-profile workstation crane

- Mobile needs → Gantry crane

2. Total Cost of Ownership Analysis

*(Keywords: *“crane investment ROI”, “overhead crane lifecycle costs”)

| Cost Factor | Top Running Crane | Underhung Crane |

|---|---|---|

| Initial Purchase | $$$$ (Higher) | $$ (Lower) |

| Installation | $$$ (Requires runway beams) | $ (Ceiling-mounted) |

| Maintenance | $$ (Robust components) | $ (Simpler system) |

| Lifespan | 25-30+ years | 15-20 years |

| Productivity ROI | High (Heavy-duty use) | Moderate (Light-duty) |

Pro Tip: A 100-ton top running crane typically pays for itself in 3-5 years through productivity gains in heavy manufacturing.

3. Future-Proofing Considerations

*(Keywords: *“smart crane upgrades”, “automation-ready cranes”)

Ask These Questions:

- Automation Potential:

- Does it support remote monitoring?

- Can it integrate with plant ERP/MES systems?

- Expansion Readiness:

- Can capacity be upgraded later?

- Is the runway designed for future bay extensions?

- Regulatory Compliance:

- Meets CMAA Class D (Heavy Duty) or FEM 1.001?

- Has CE/OSHA certifications?

Final Recommendation

*(Keywords: *“best industrial crane solution”, “expert crane advice”)

Top running cranes deliver unmatched value when:

✅ Your loads exceed 20 tons regularly

✅ Your facility has strong overhead support structures

✅ You require precision handling of valuable loads

For lighter needs (<10 tons), consider:

- Underhung cranes

- Modular workstation cranes

- Mobile gantry systems

Call-to-Action

“Still unsure? Get a personalized recommendation:

[📞 Schedule a free crane consultation]

[📧 Request a quote with 3D layout]