Optimizing Manufacturing & Automotive Workflows: The Essential Guide to Workshop Cranes

Introduction

In manufacturing and automotive production, precision, speed, and worker safety are non-negotiable. Workshop cranes play a pivotal role in assembly lines, component handling, and maintenance, helping factories boost productivity, reduce downtime, and minimize workplace injuries.

This guide covers:

✅ Best crane types for automotive & manufacturing

✅ How smart crane tech enhances efficiency

✅ Key features for heavy-duty industrial use

✅ Safety and ROI considerations

Why Manufacturing Needs Specialized Cranes

Manual lifting in production environments leads to:

✖ Bottlenecks in assembly lines

✖ Increased defect rates from improper handling

✖ Worker fatigue and injury risks

✖ Costly equipment damage

The right industrial crane system solves these challenges by:

✔ Enabling precise positioning (±1mm accuracy for sensitive components)

✔ Accelerating cycle times (3-5x faster than forklifts for in-plant moves)

✔ Reducing labor strain (eliminating risky manual lifts)

✔ Integrating with automation (seamless robotic cell coordination)

Best Crane Types for Manufacturing & Automotive

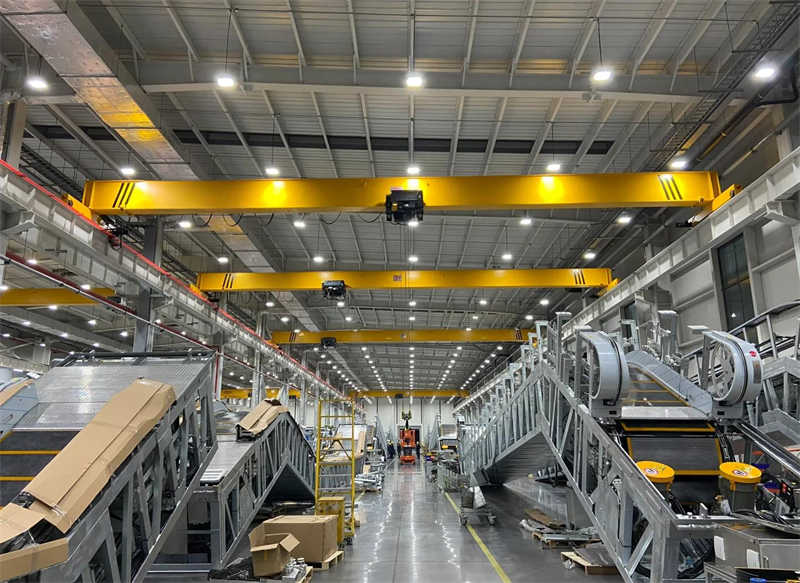

1. Bridge Cranes (Overhead Cranes) – The Production Line Backbone

Best for: High-volume assembly plants, stamping facilities

Capacity: 5-100+ tons

Key Benefits:

- Full facility coverage with runway systems

- Precision controls for delicate part placement

- Automation-ready (PLC-controlled movements)

- Custom configurations (explosion-proof, cleanroom variants)

Ideal Applications:

- Engine block transfers

- Press line feeding

- Robotic weld cell servicing

2. Jib Cranes – Flexible Workstation Solutions

Best for: Component staging areas, maintenance bays

Capacity: 0.5-10 tons

Key Benefits:

- 270°-360° rotation for multi-station access

- Modular designs (wall-mounted, freestanding, articulating)

- Fast deployment (install in hours vs. weeks)

Ideal Applications:

- Machined part loading/unloading

- Die changes in press shops

- Electric vehicle battery handling

3. Gantry Cranes – For Heavy Component Movement

Best for: Large part transfers, outdoor storage yards

Capacity: 10-200+ tons

Key Benefits:

- No building modifications required

- Mobile configurations (rail-mounted or rubber-tired)

- Wide spans (up to 30m for frame handling)

Ideal Applications:

- Chassis assembly lines

- Stamping plant scrap removal

- Turbine/transformer handling

4. Smart Hoist Systems – The Automation Edge

Best for: Industry 4.0 smart factories

Features:

- AI-powered load sensing (auto weight detection)

- Vision-guided positioning (camera-assisted alignment)

- Predictive maintenance (IoT vibration monitoring)

ROI Drivers:

- 30% faster changeovers

- 50% reduction in handling damage

- Real-time production data integration

Critical Features for Industrial Cranes

When specifying cranes for manufacturing, prioritize:

🔹 Precision Controls

- Variable frequency drives (VFD) for smooth acceleration

- Micro-speed modes (<1 m/min for delicate placement)

🔹 Durability Enhancements

- Class FEM/ISO duty cycle ratings

- Corrosion-resistant coatings for paint shops

🔹 Safety Systems

- Overload protection (mechanical + electronic)

- Emergency power-down circuits

- Anti-sway technology for long-span lifts

🔹 Future-Proofing

- Modular designs for capacity upgrades

- Open API architecture for MES integration

Case Study: Automotive Tier 1 Supplier Transformation

A major auto parts manufacturer implemented AI-enhanced bridge cranes featuring:

- Automated tool changing

- Digital twin synchronization

- Collision avoidance systems

Results in 12 Months:

✔ 22% increase in press line output

✔ Zero handling-related defects

✔ ROI achieved in 14 months

Selection Guide: Matching Cranes to Applications

| Application | Recommended Crane | Why It Works |

|---|---|---|

| Body-in-white assembly | Automated bridge crane | Precise panel positioning |

| Powertrain machining | Articulating jib crane | Multi-machine servicing |

| Stamping plant | 50-ton gantry crane | Die set handling |

| Battery production | Cleanroom hoist system | Contamination control |

Key Purchasing Considerations

- Cycle Time Requirements → VFD controls reduce move times by 40%

- Floor Space Constraints → Rotary jib cranes maximize tight areas

- Future Expansion Plans → Modular runway systems allow easy extension

- Regulatory Compliance → CMAA Class D/F for heavy industrial use

The Smart Choice for Modern Factories

- High-Mix Production: Smart cranes with quick-change tooling

- Heavy Industry: Robust gantry systems with ≥25% safety margin

- EV Transition: Specialized battery handling solutions

Ready to Upgrade Your Material Handling?

➡ Our industrial crane experts can design a custom solution for your production needs.